3D Print Minimal Surface - 2021_ARCH 571 - University of Michigan

by Clark Cheng

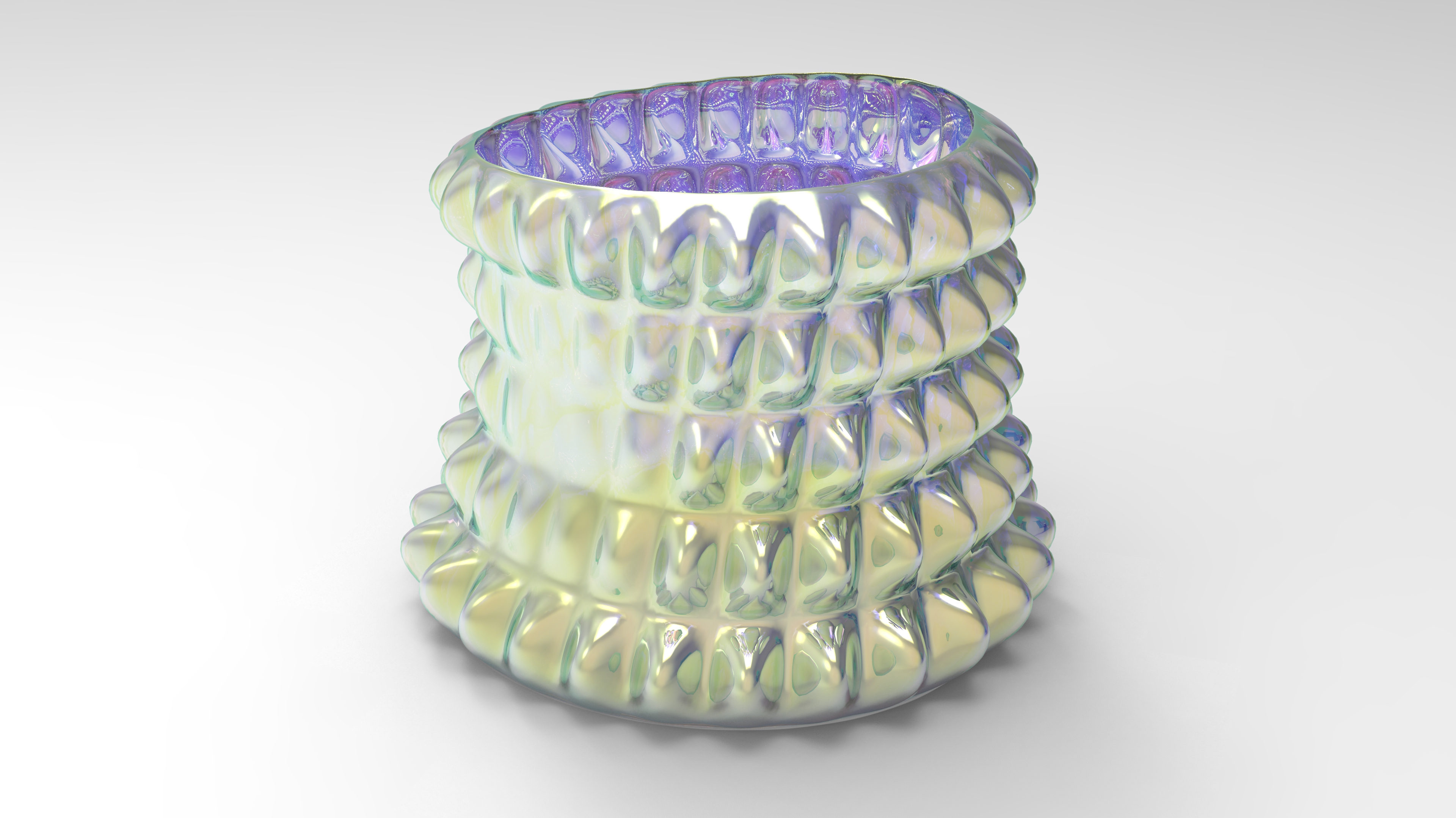

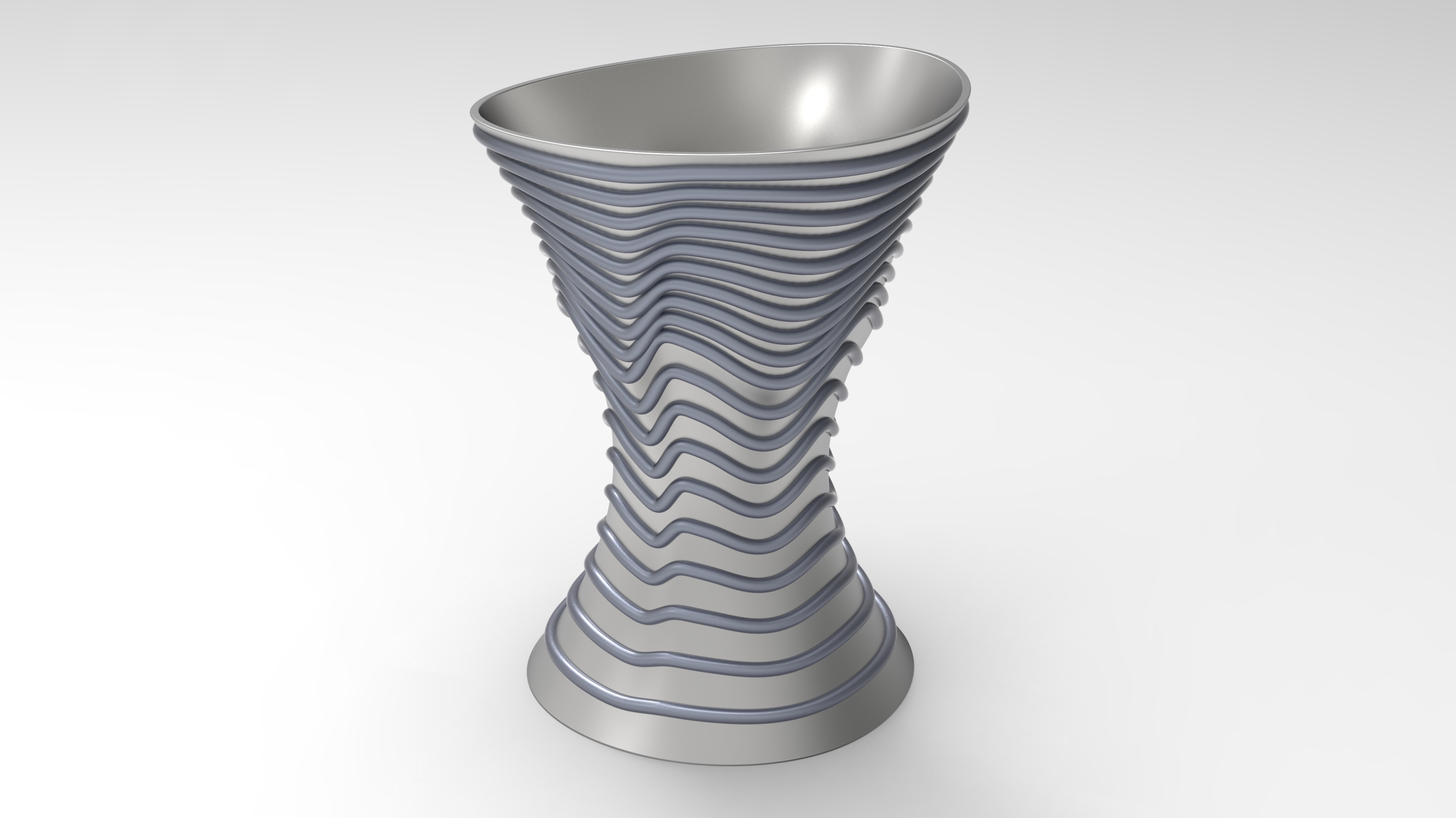

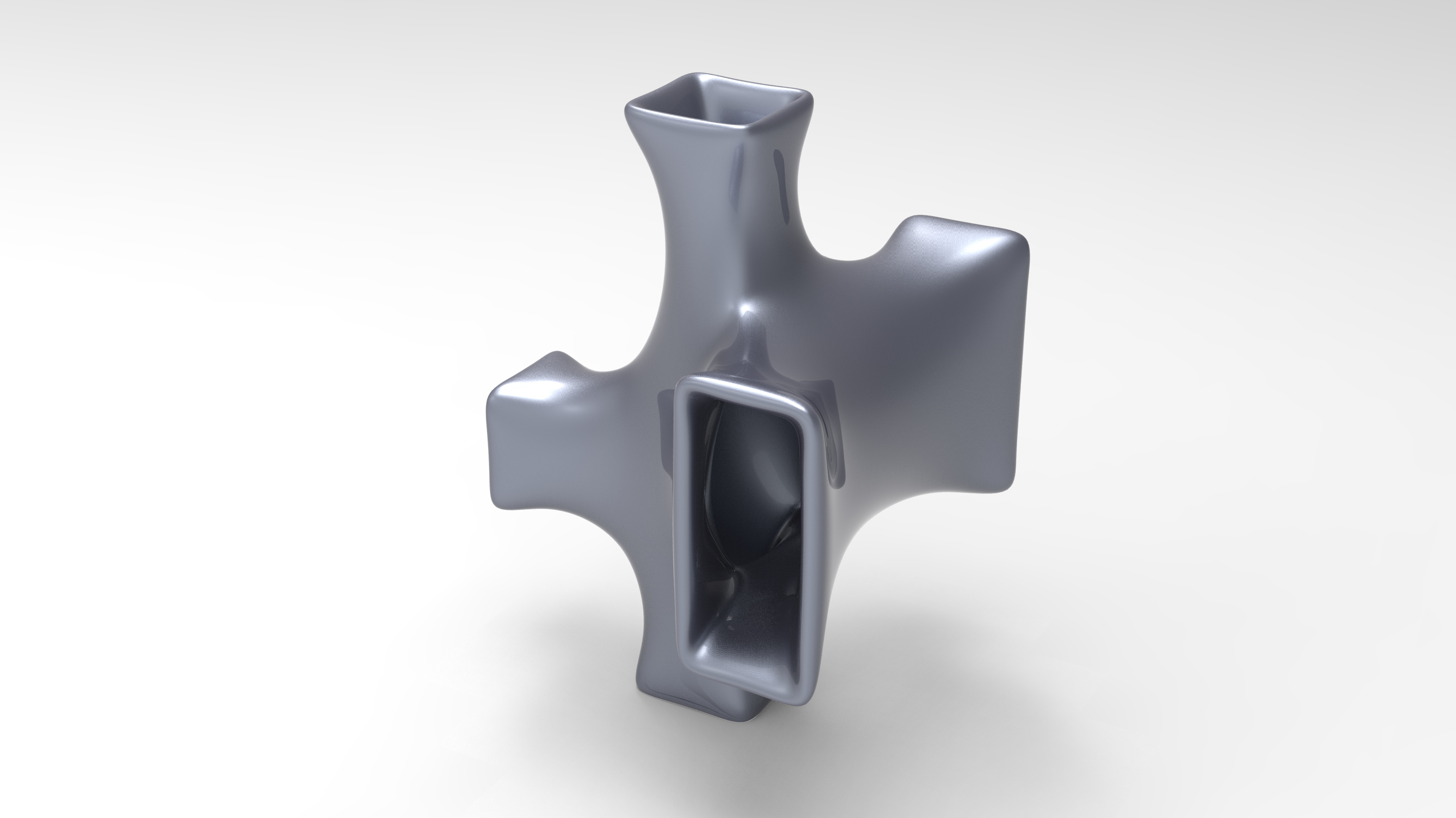

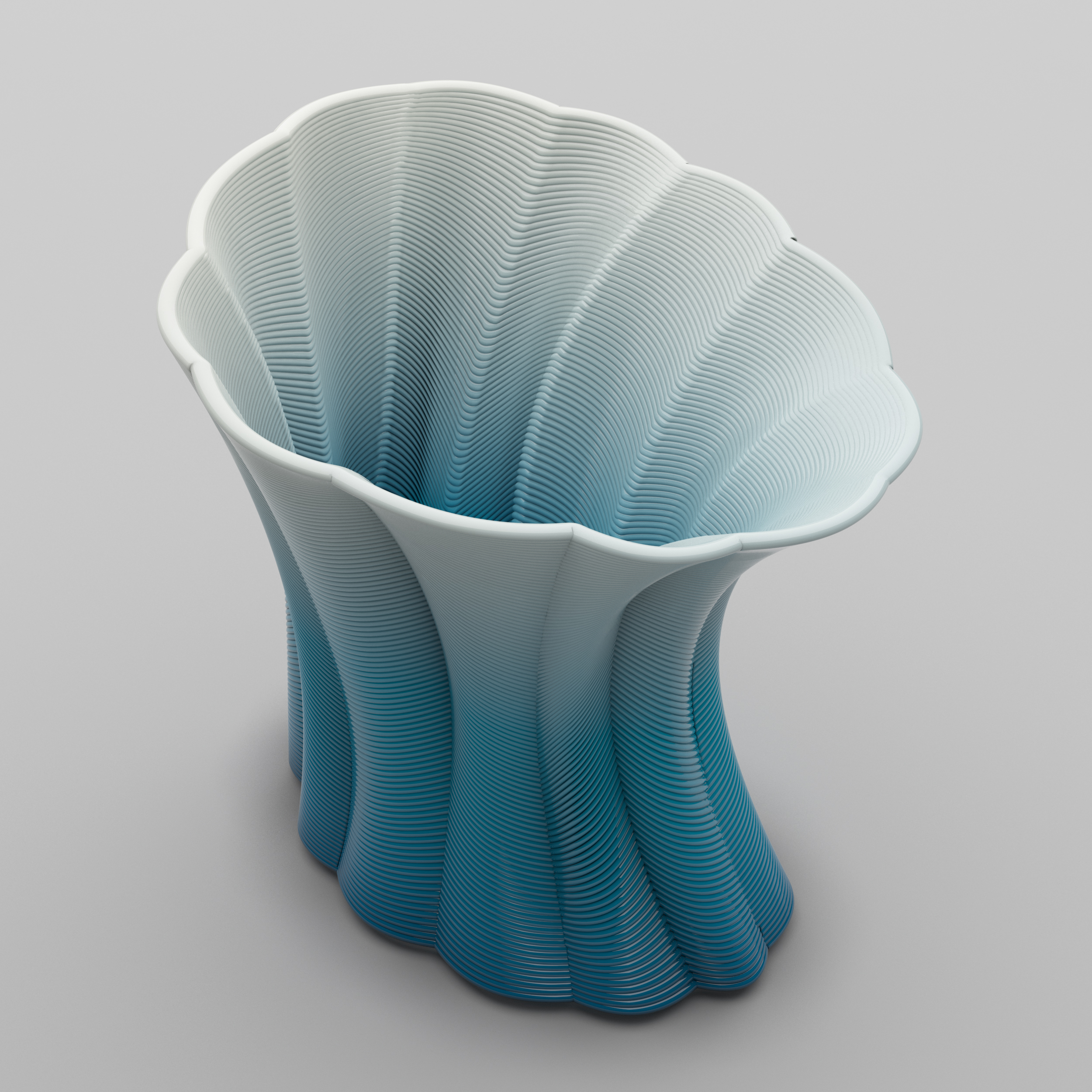

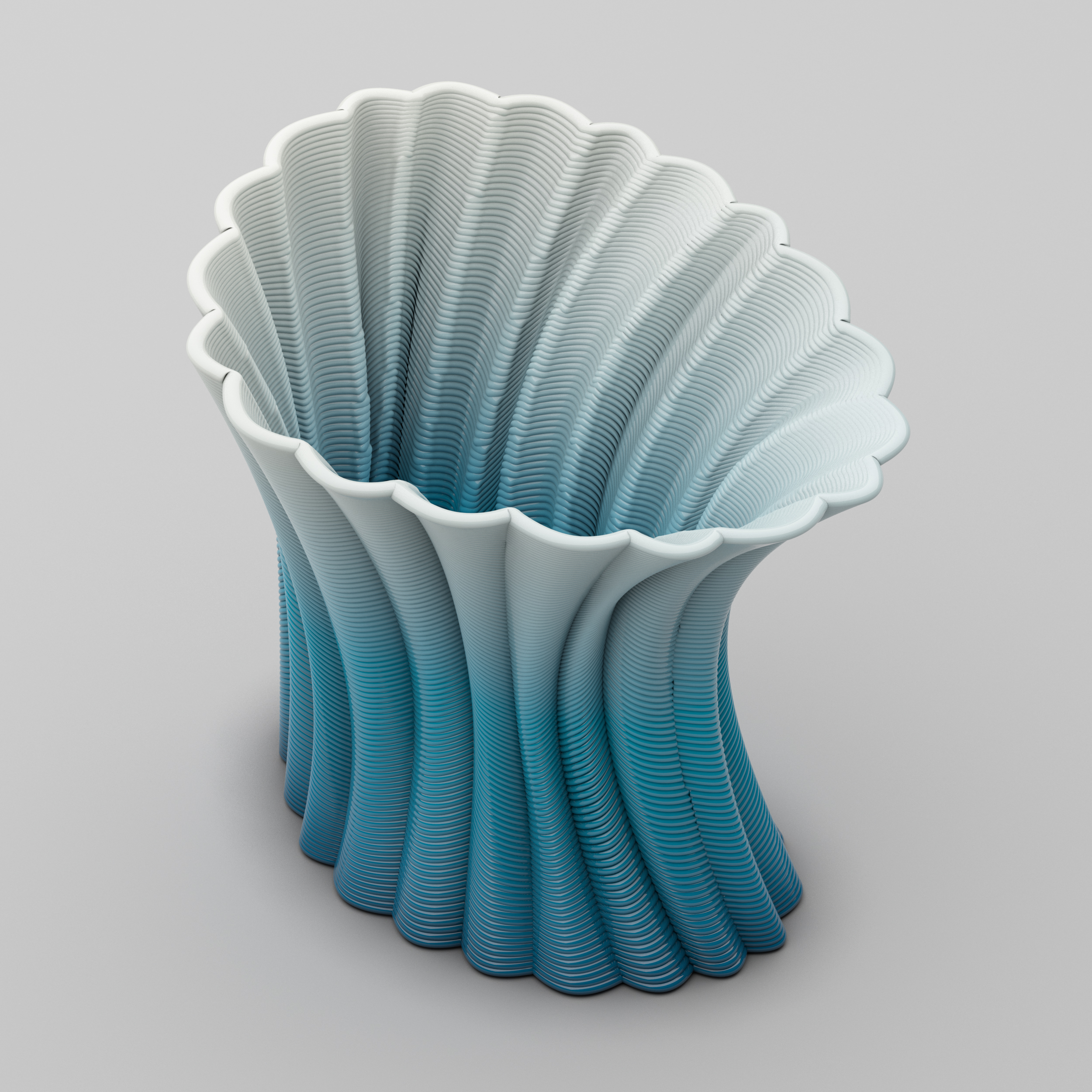

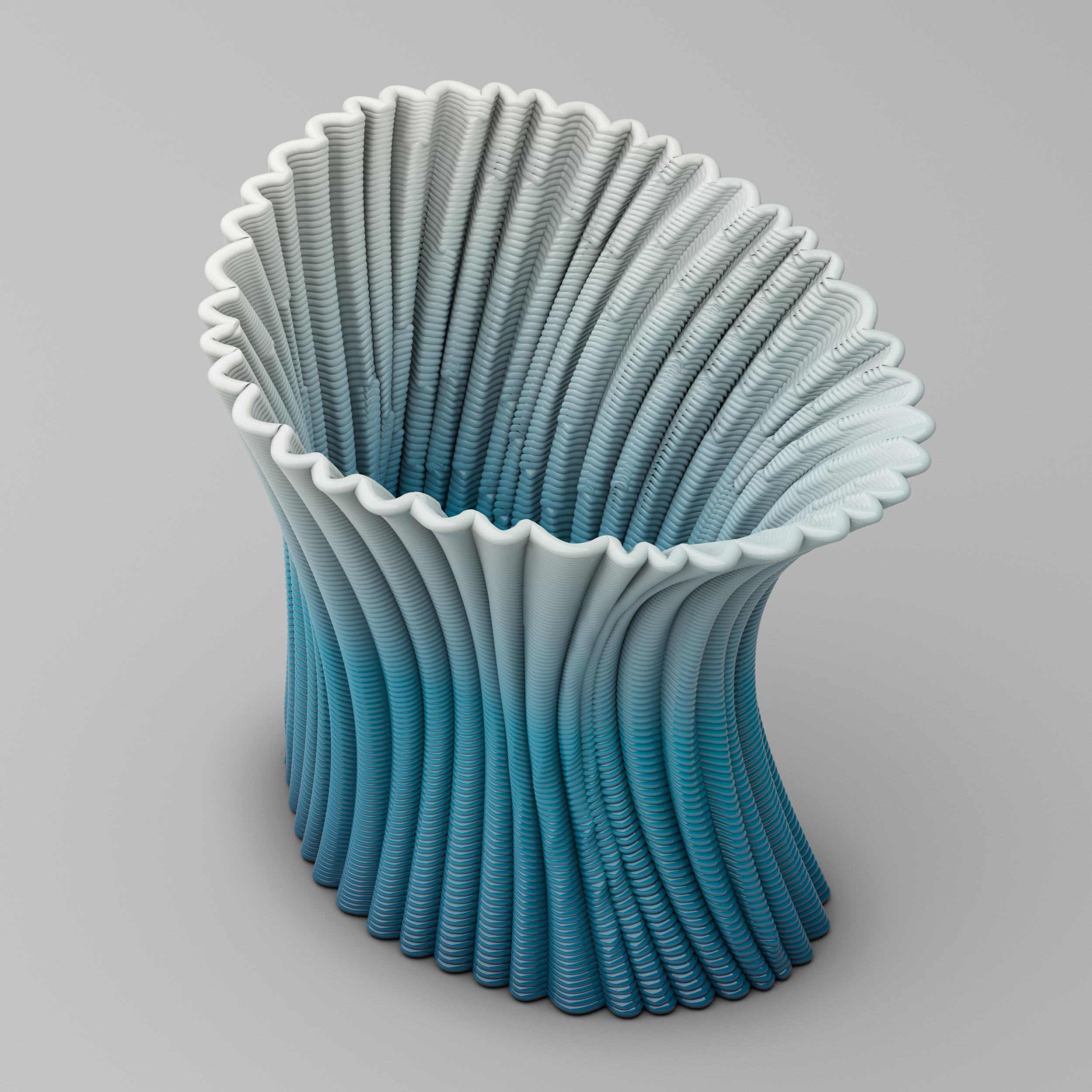

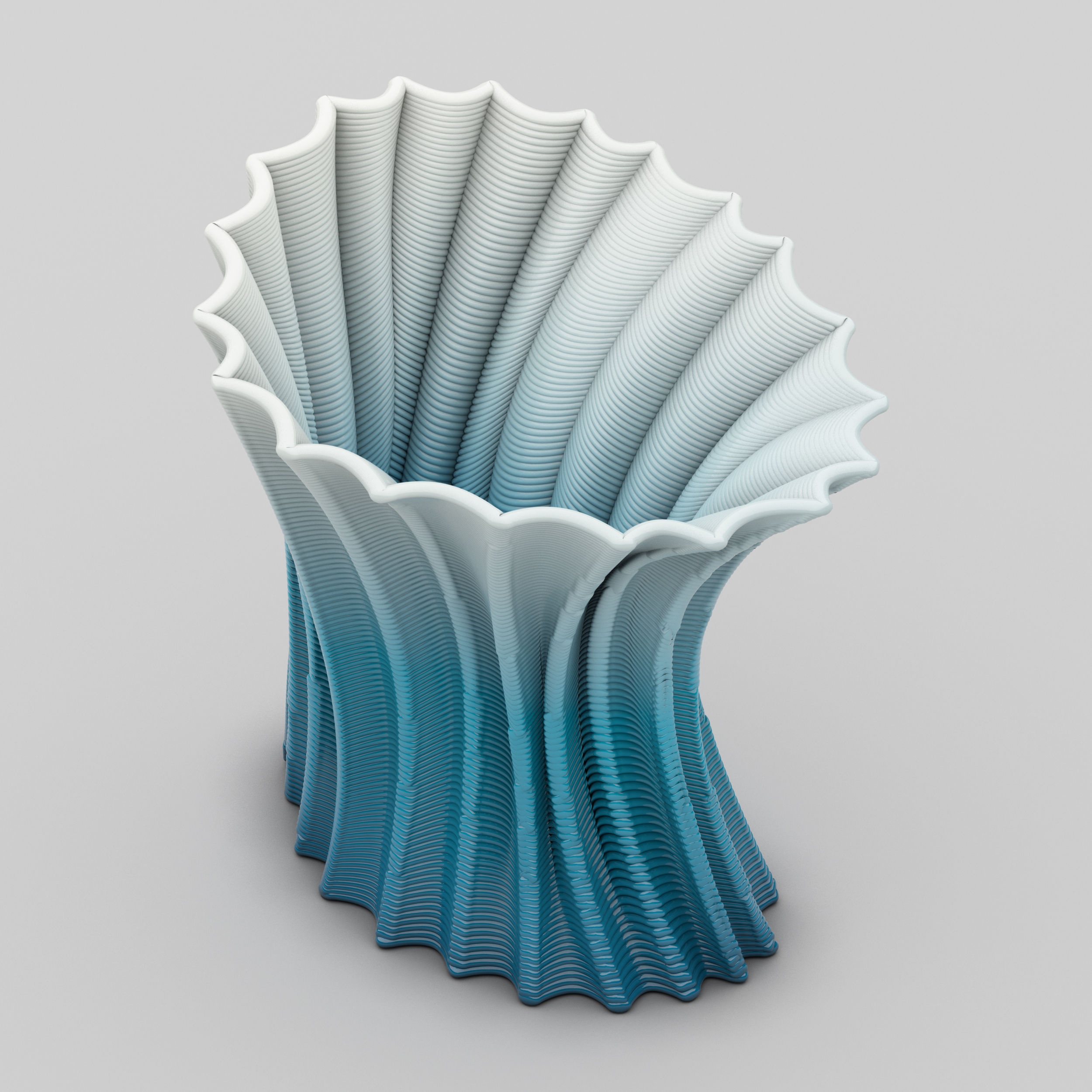

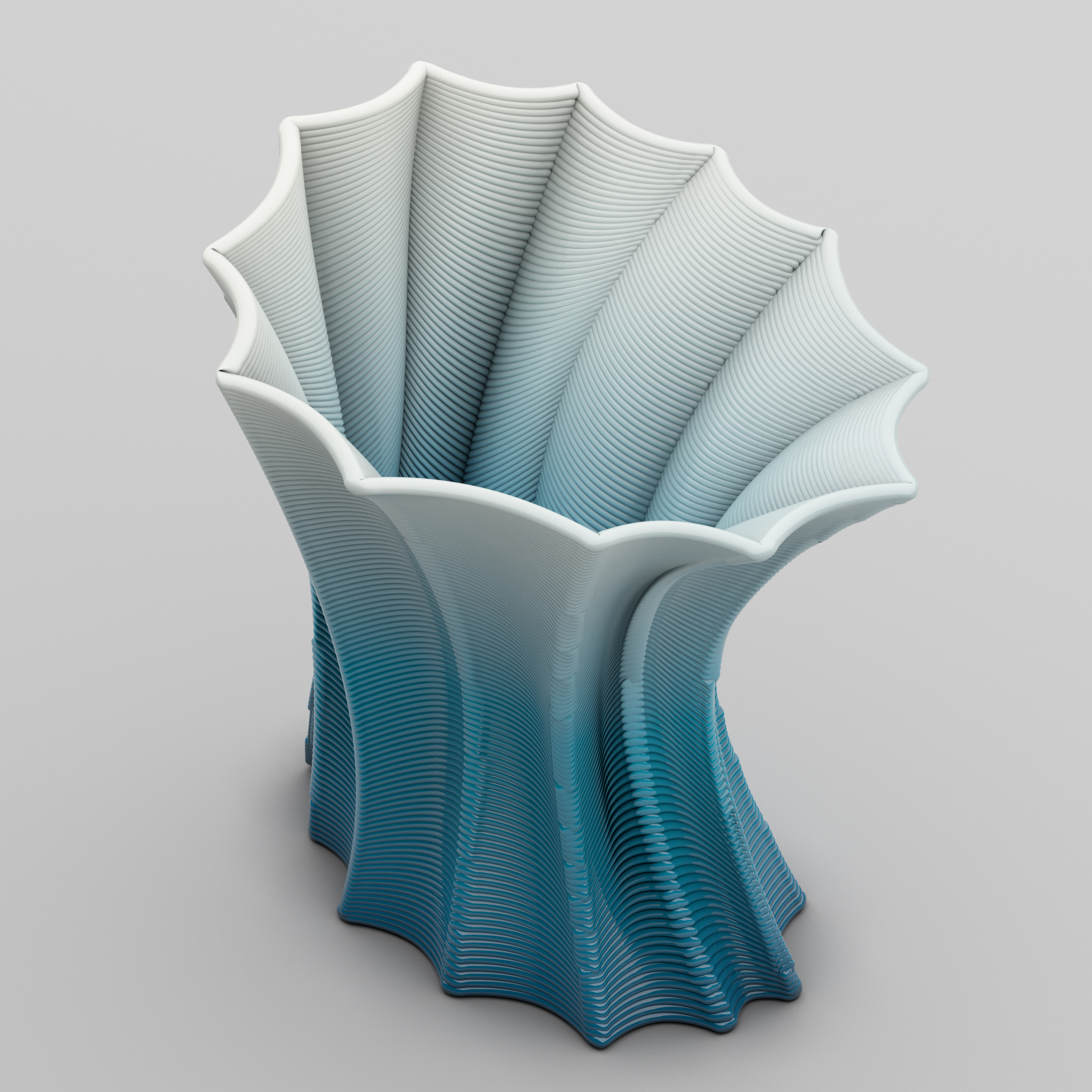

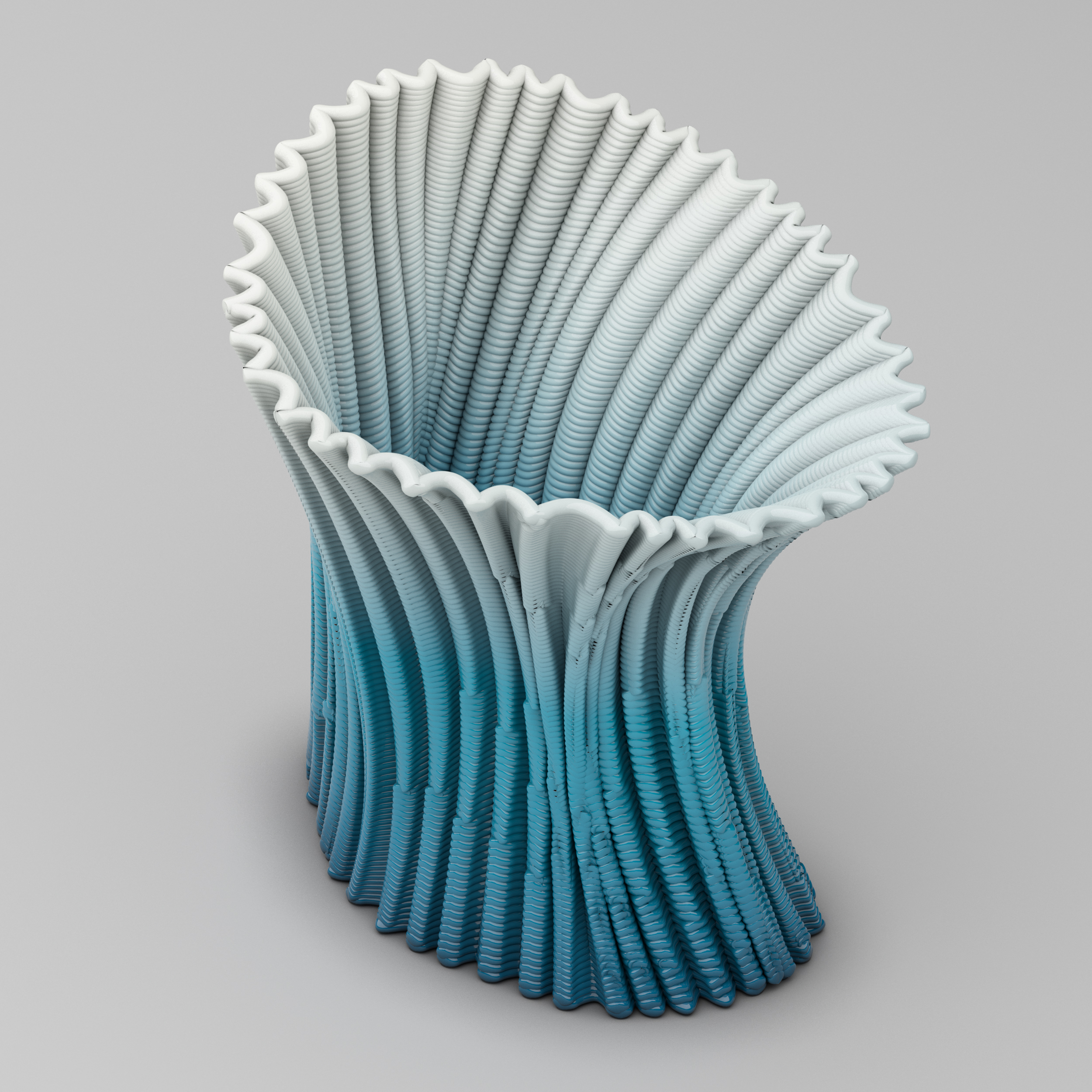

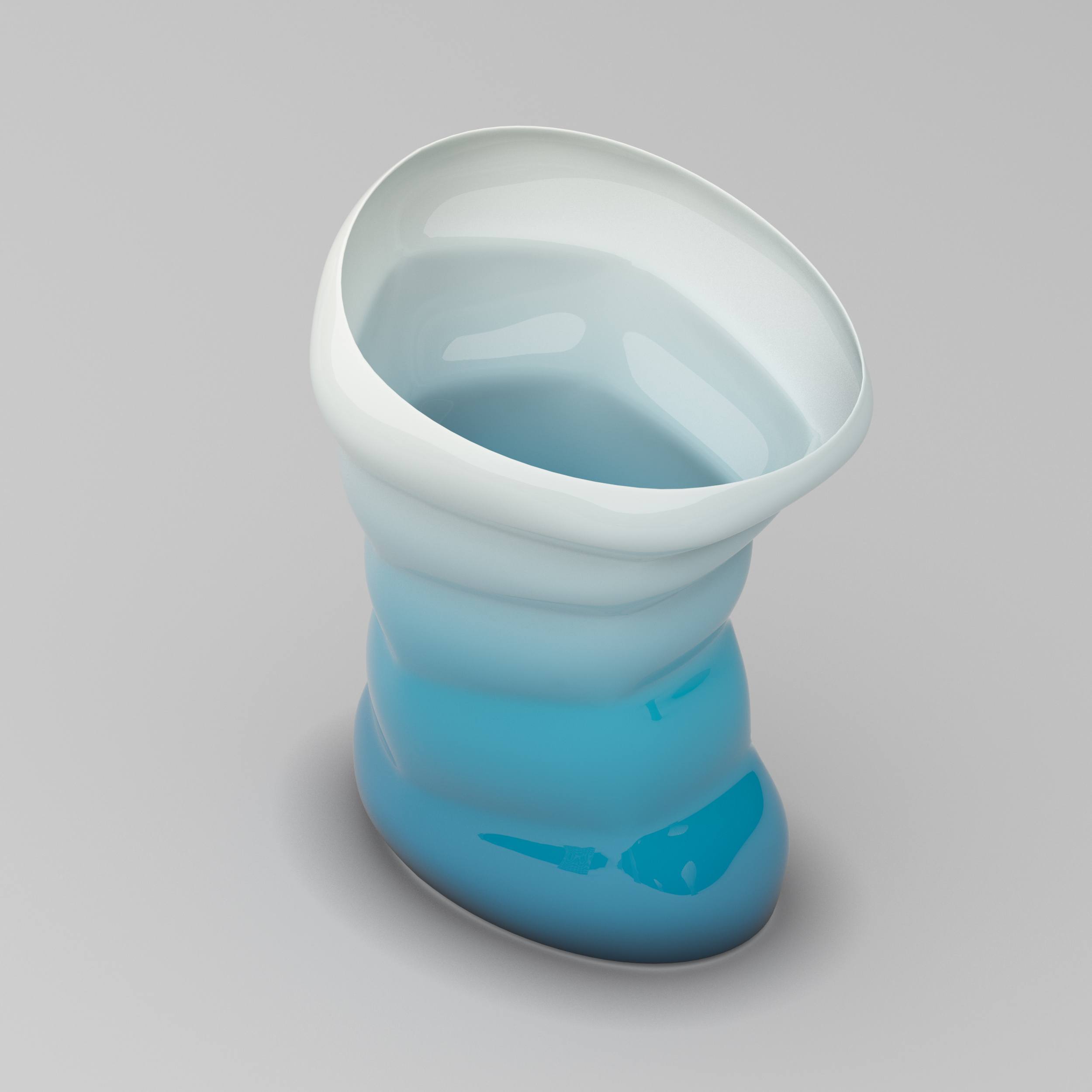

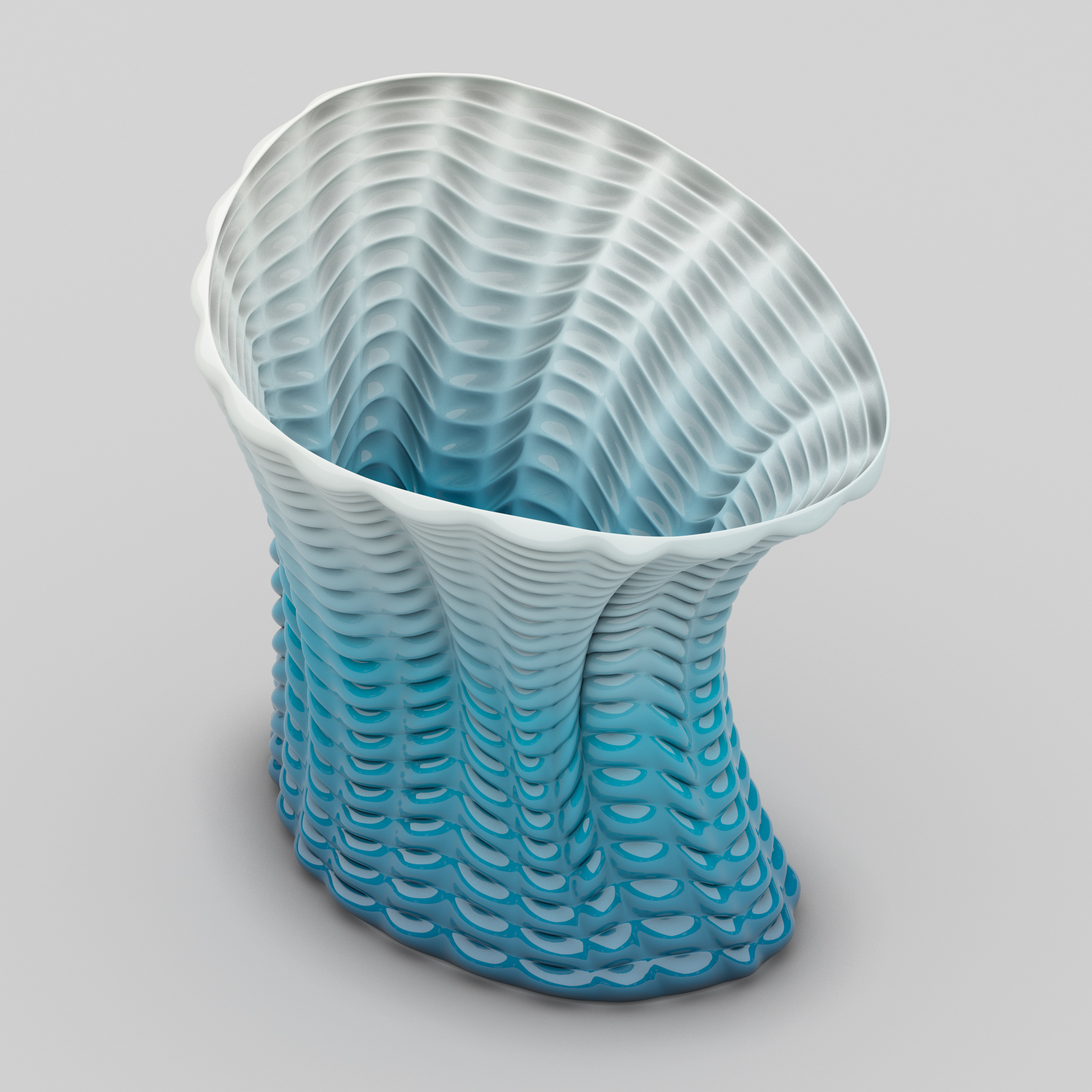

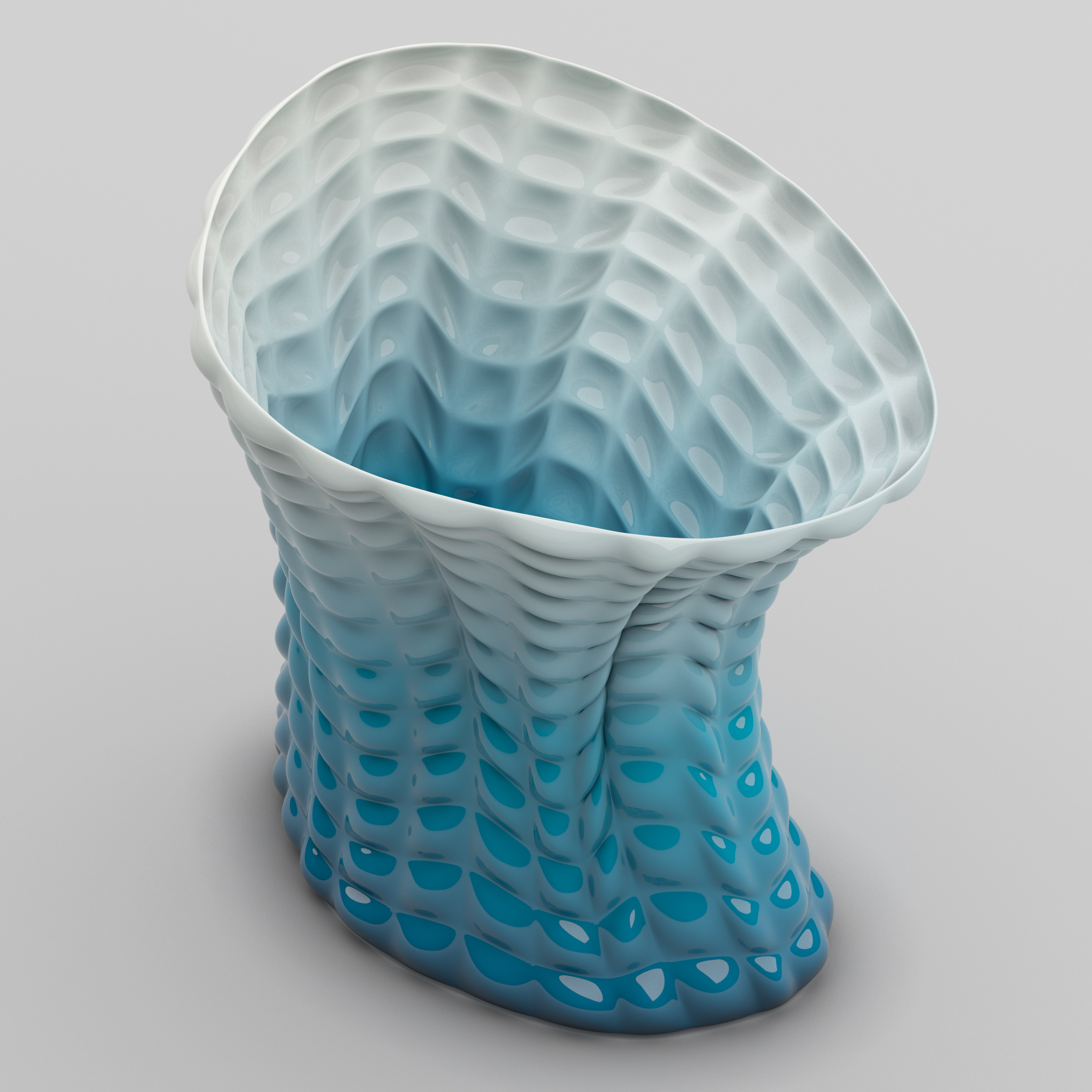

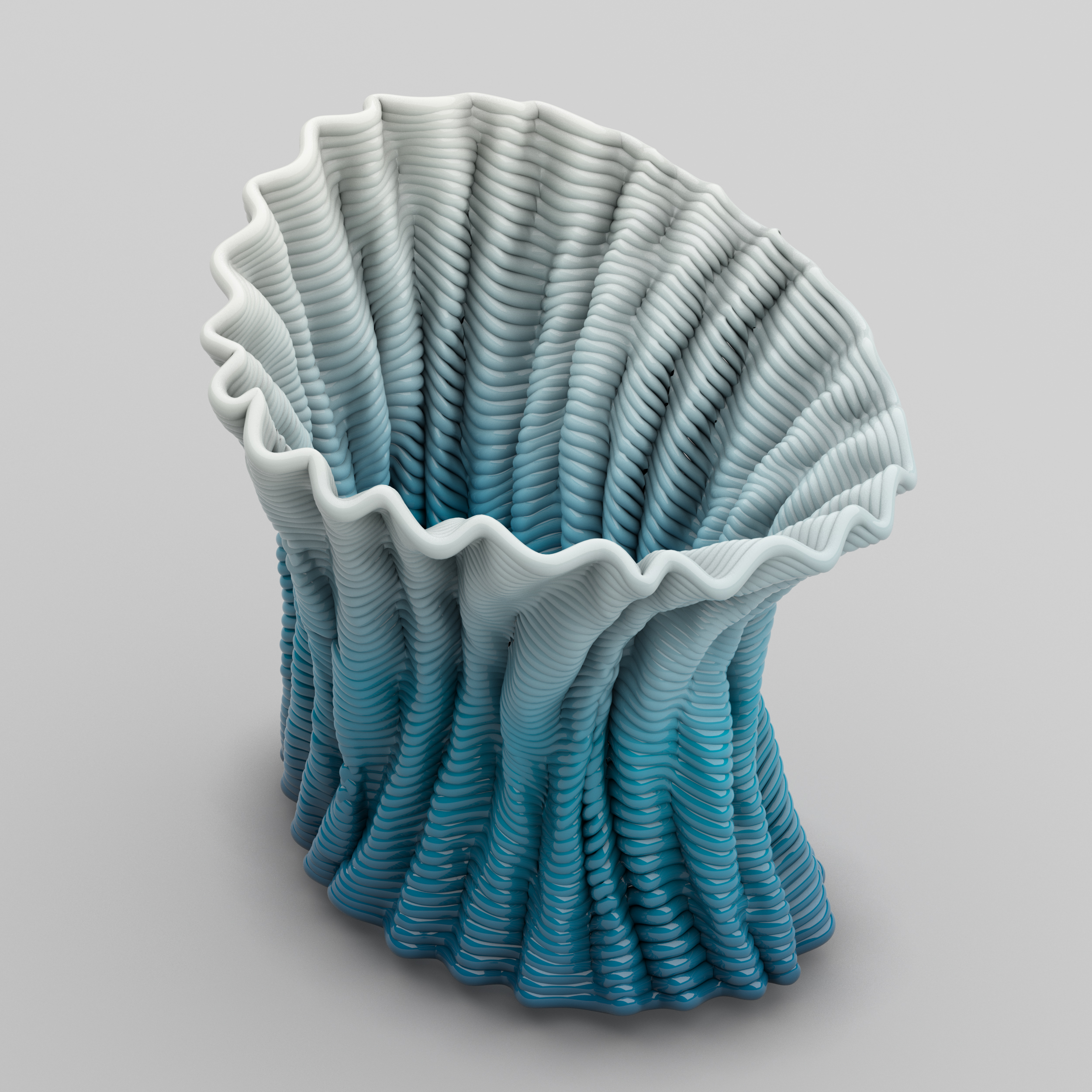

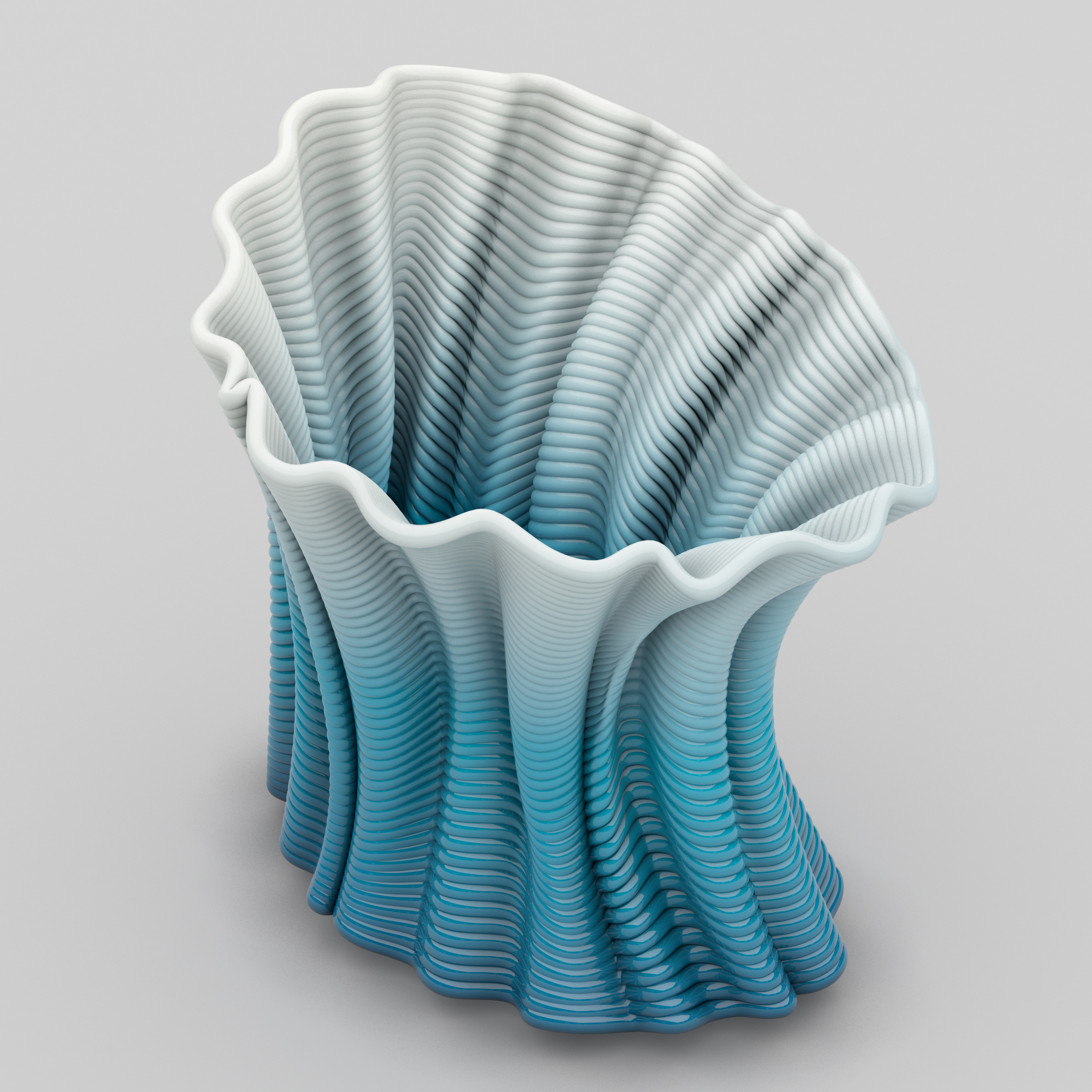

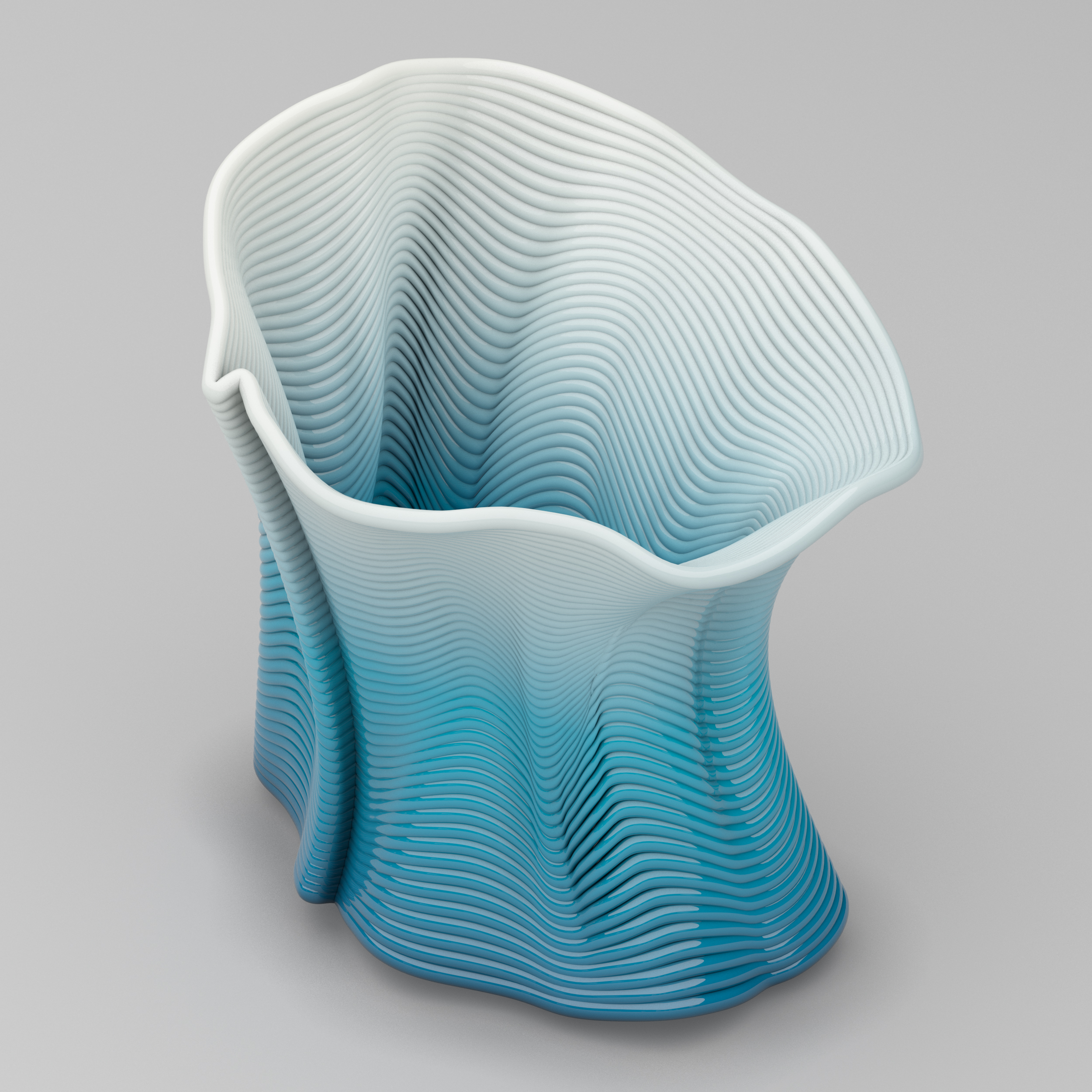

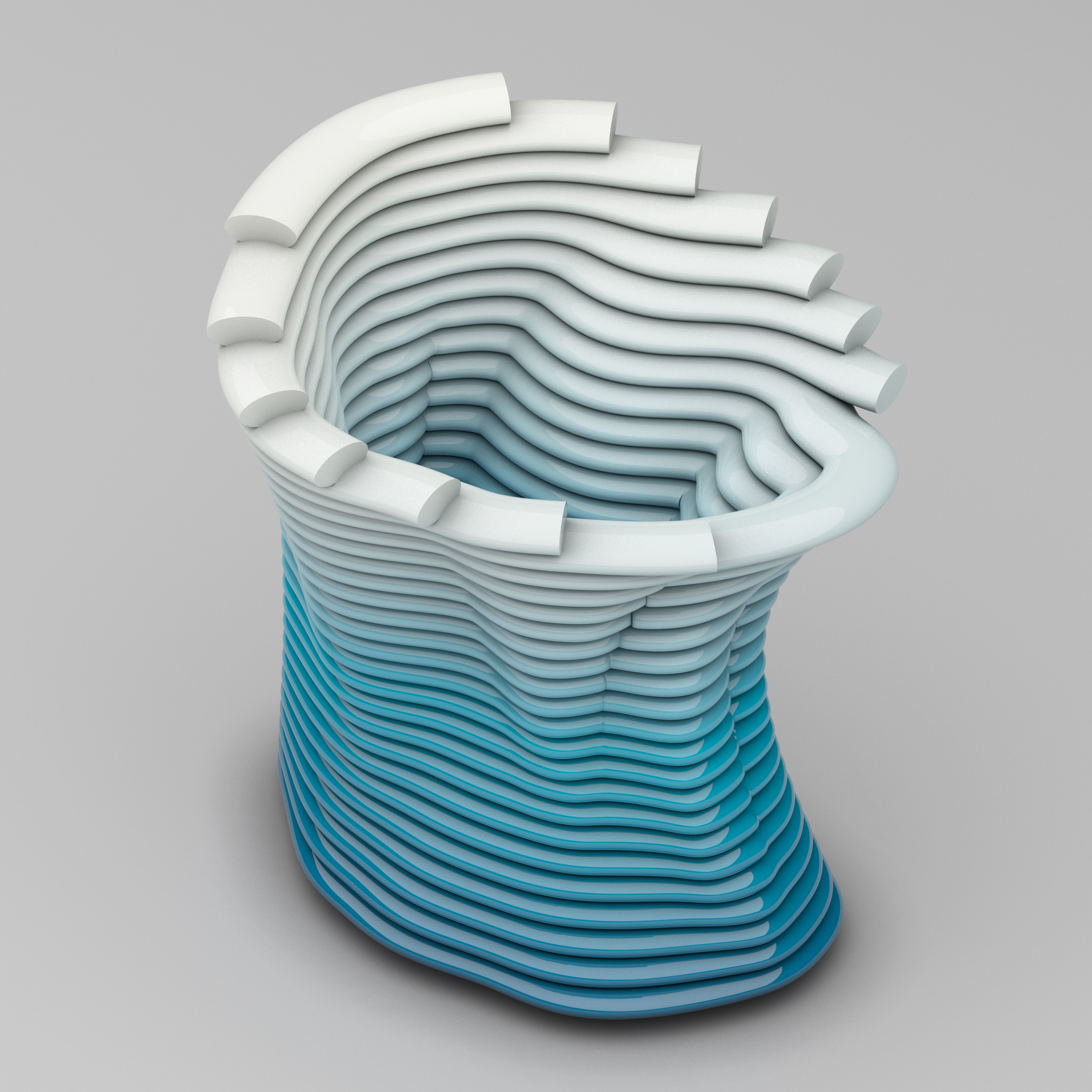

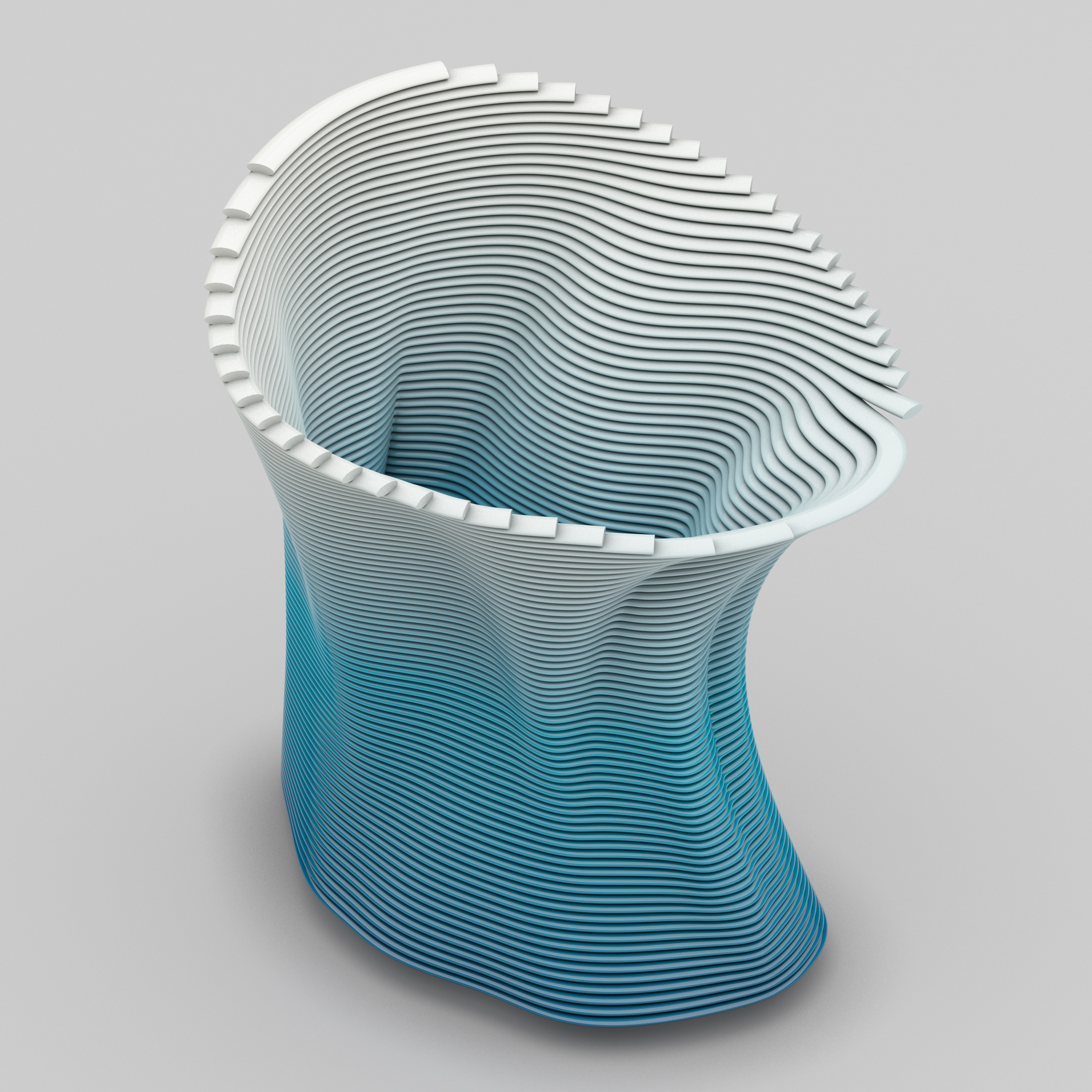

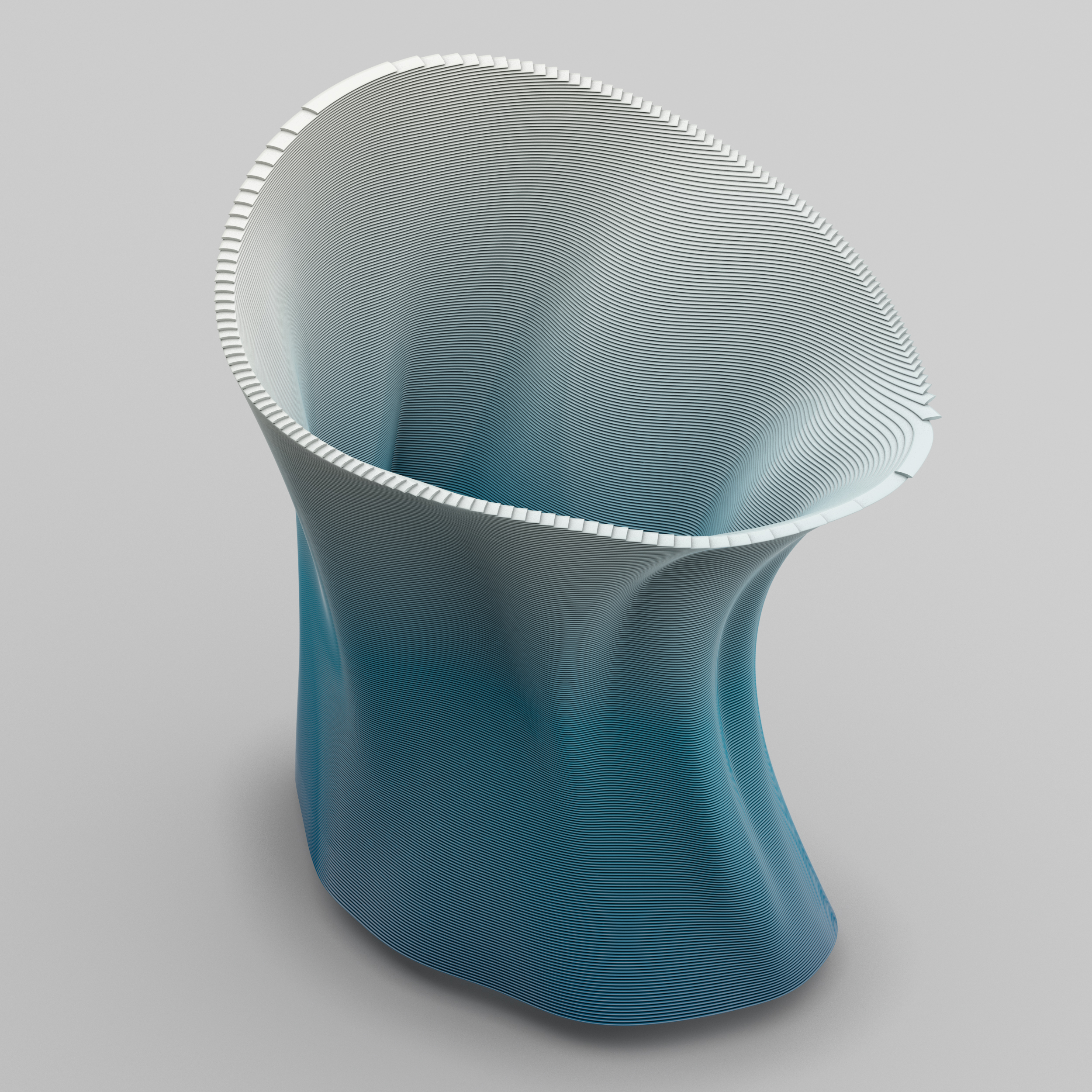

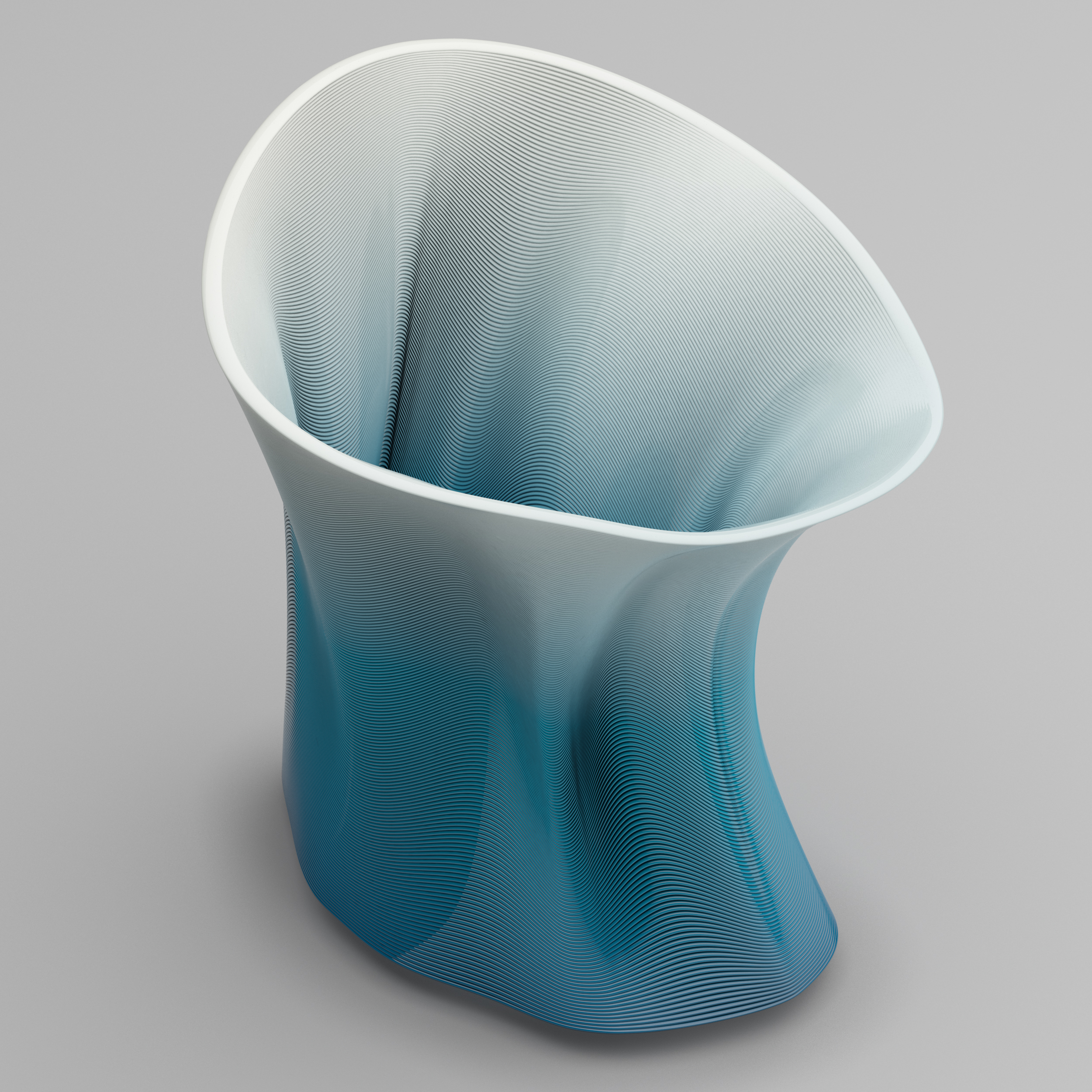

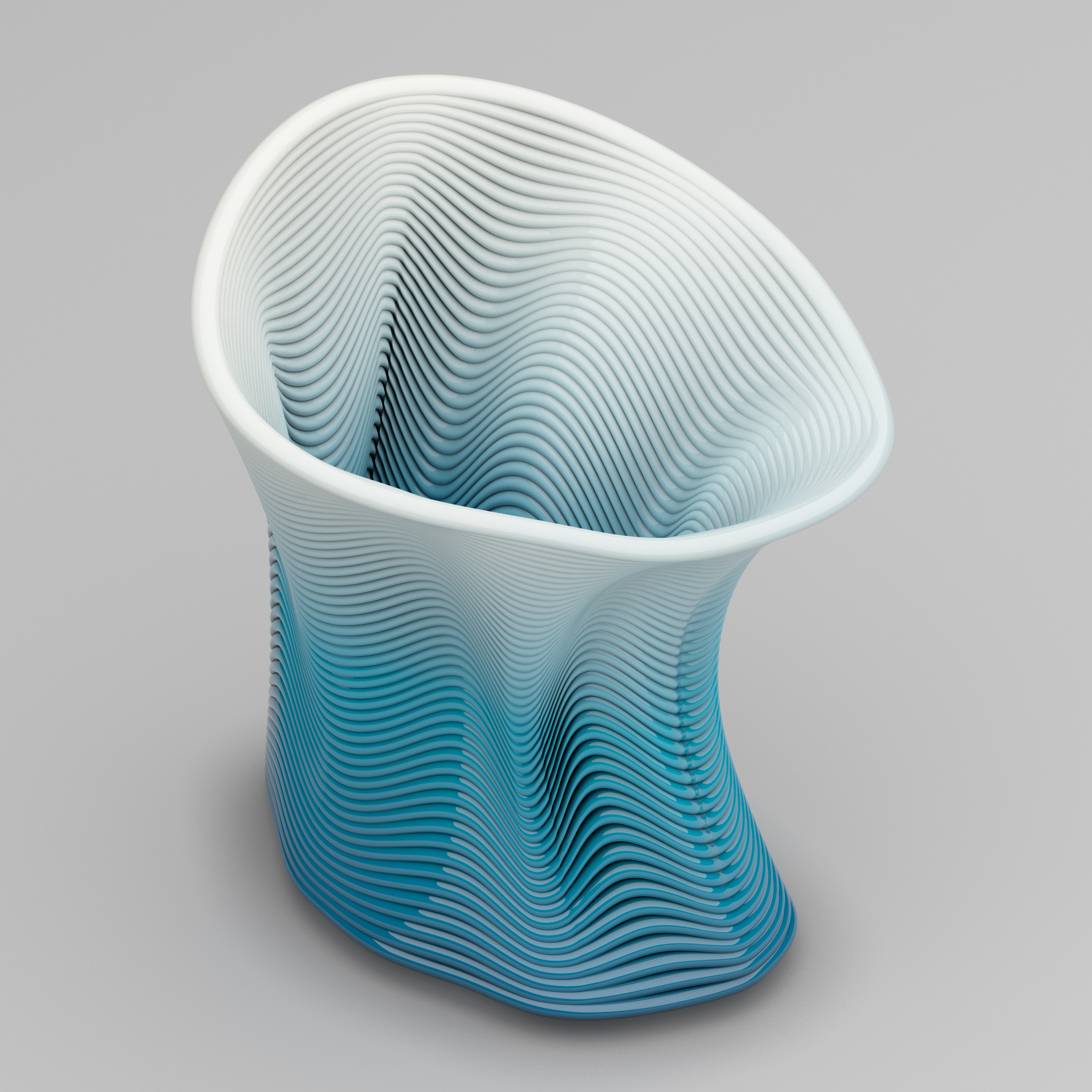

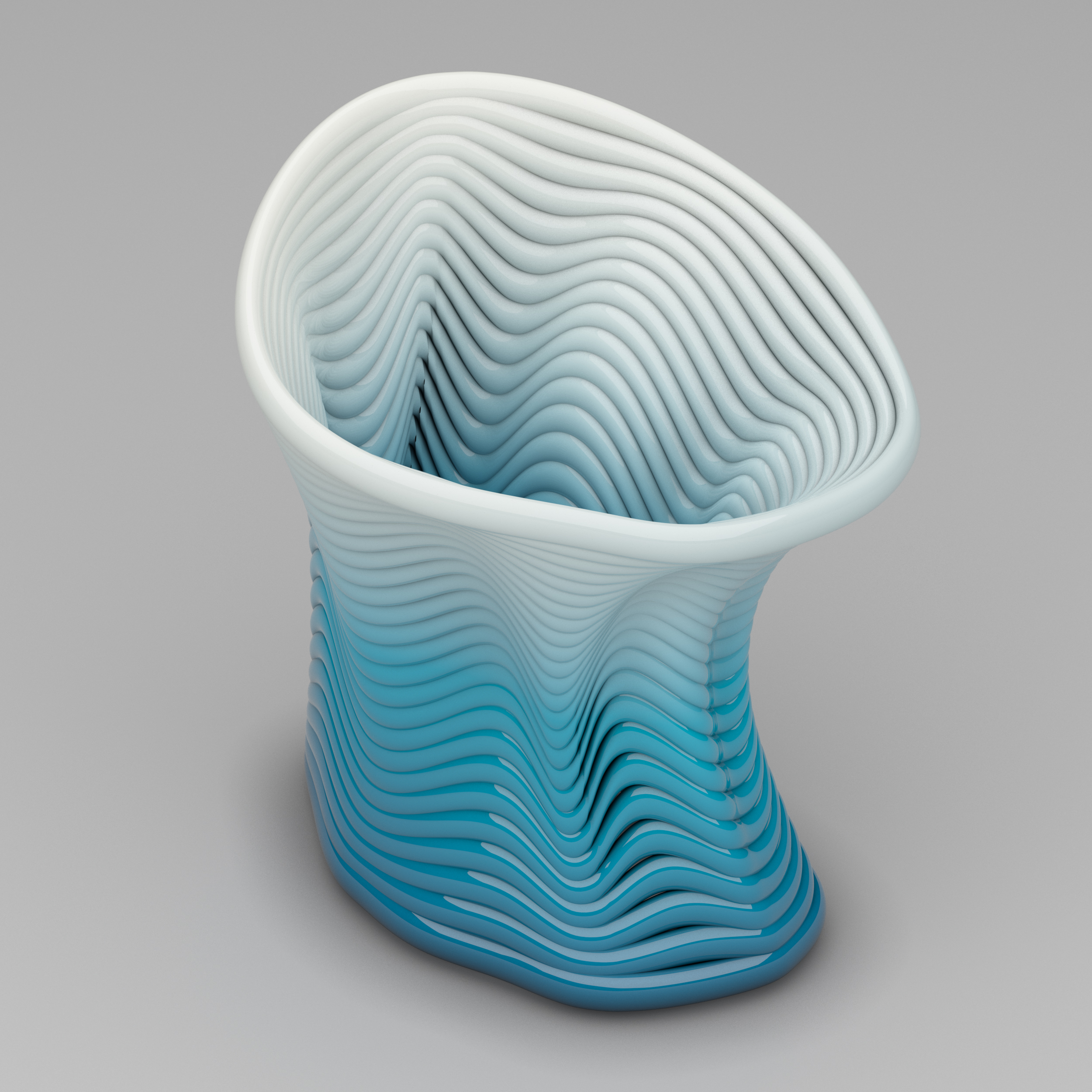

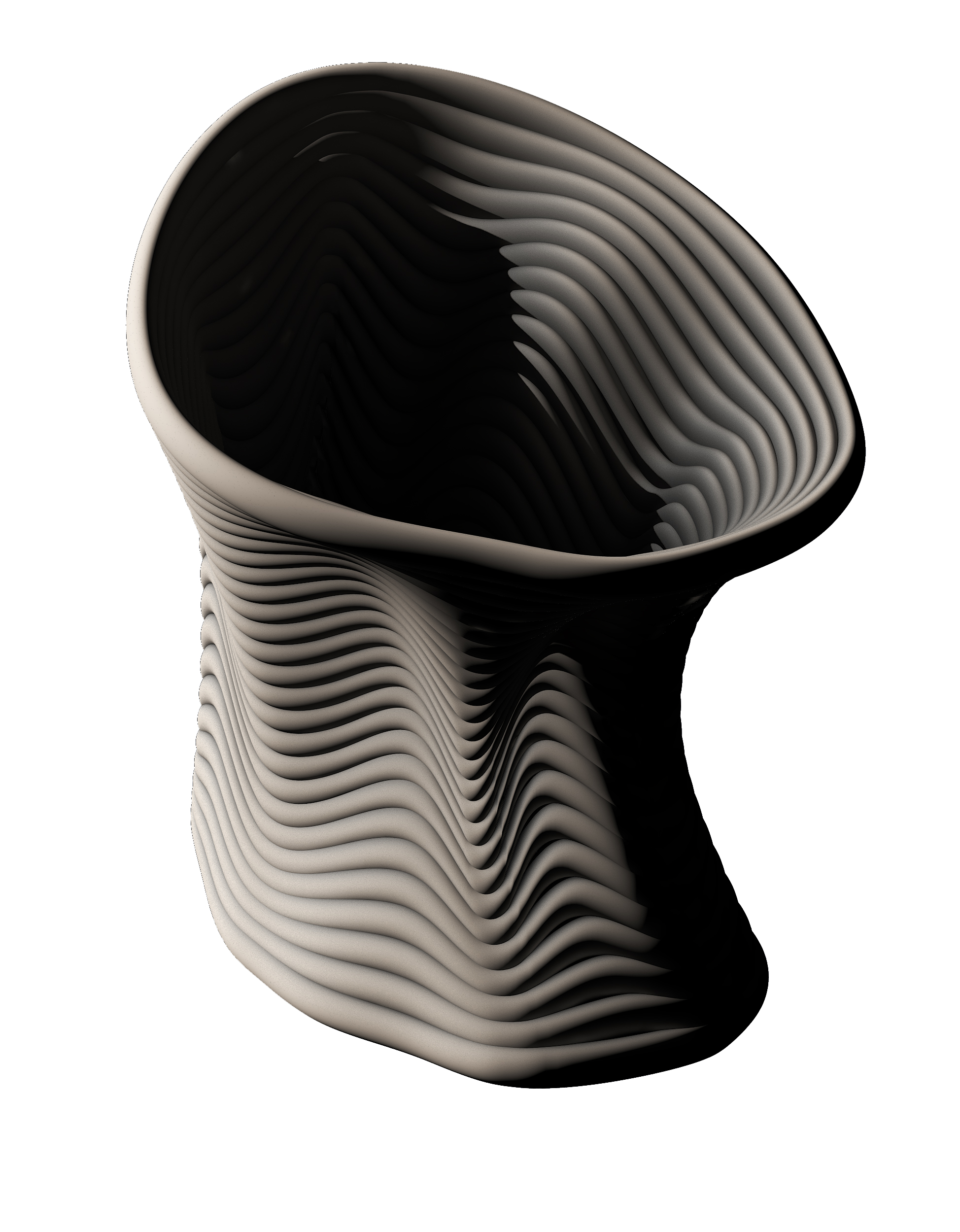

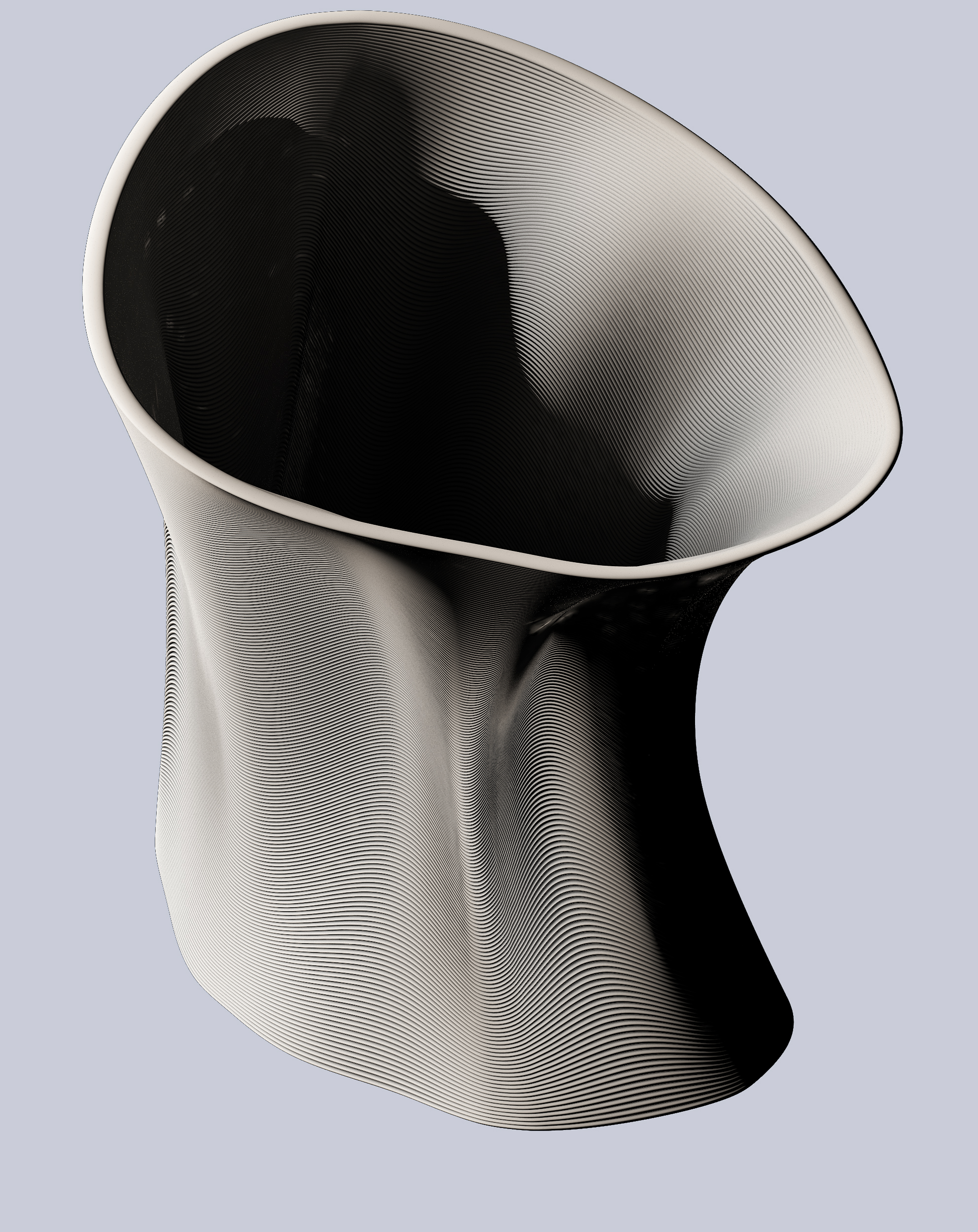

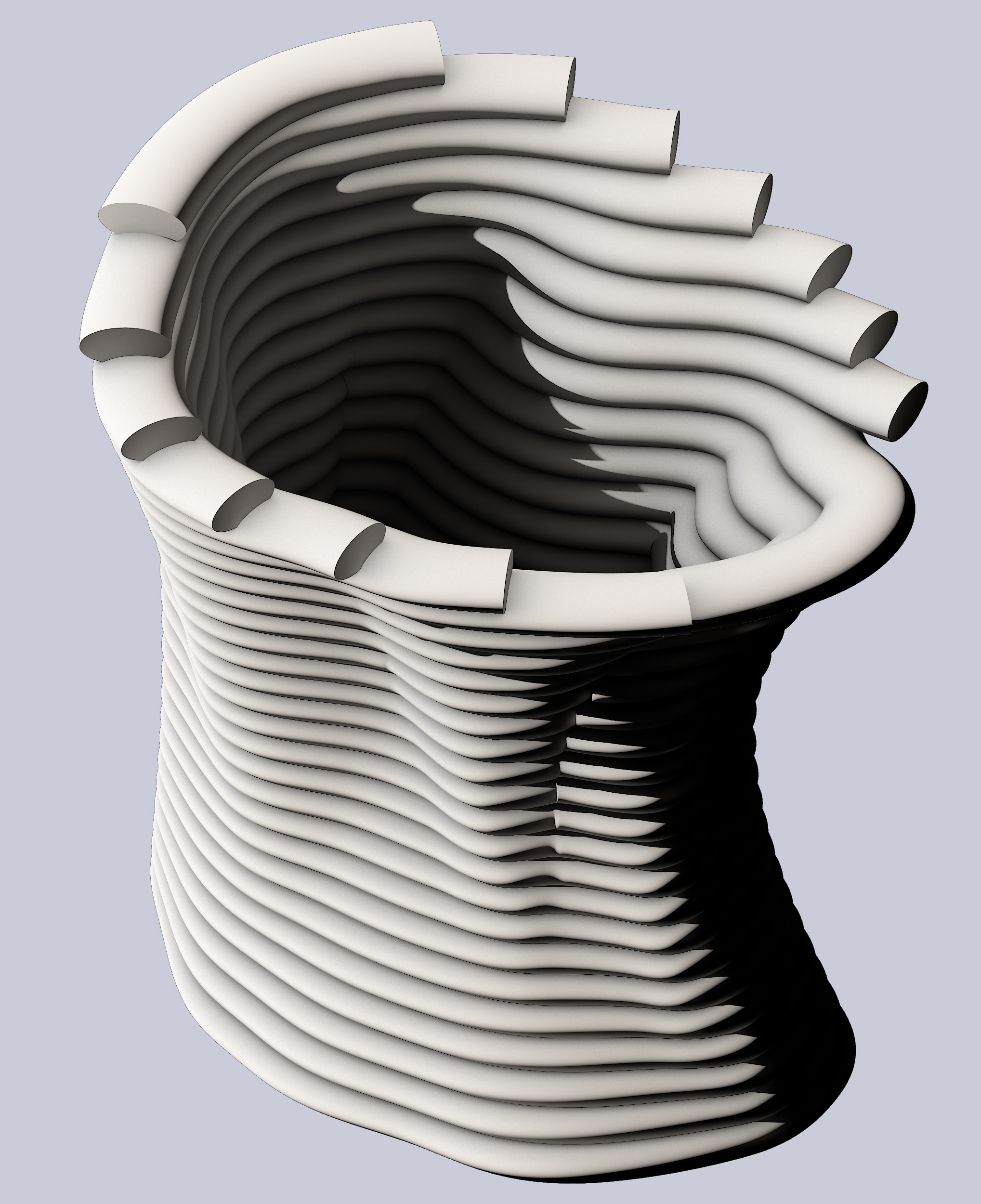

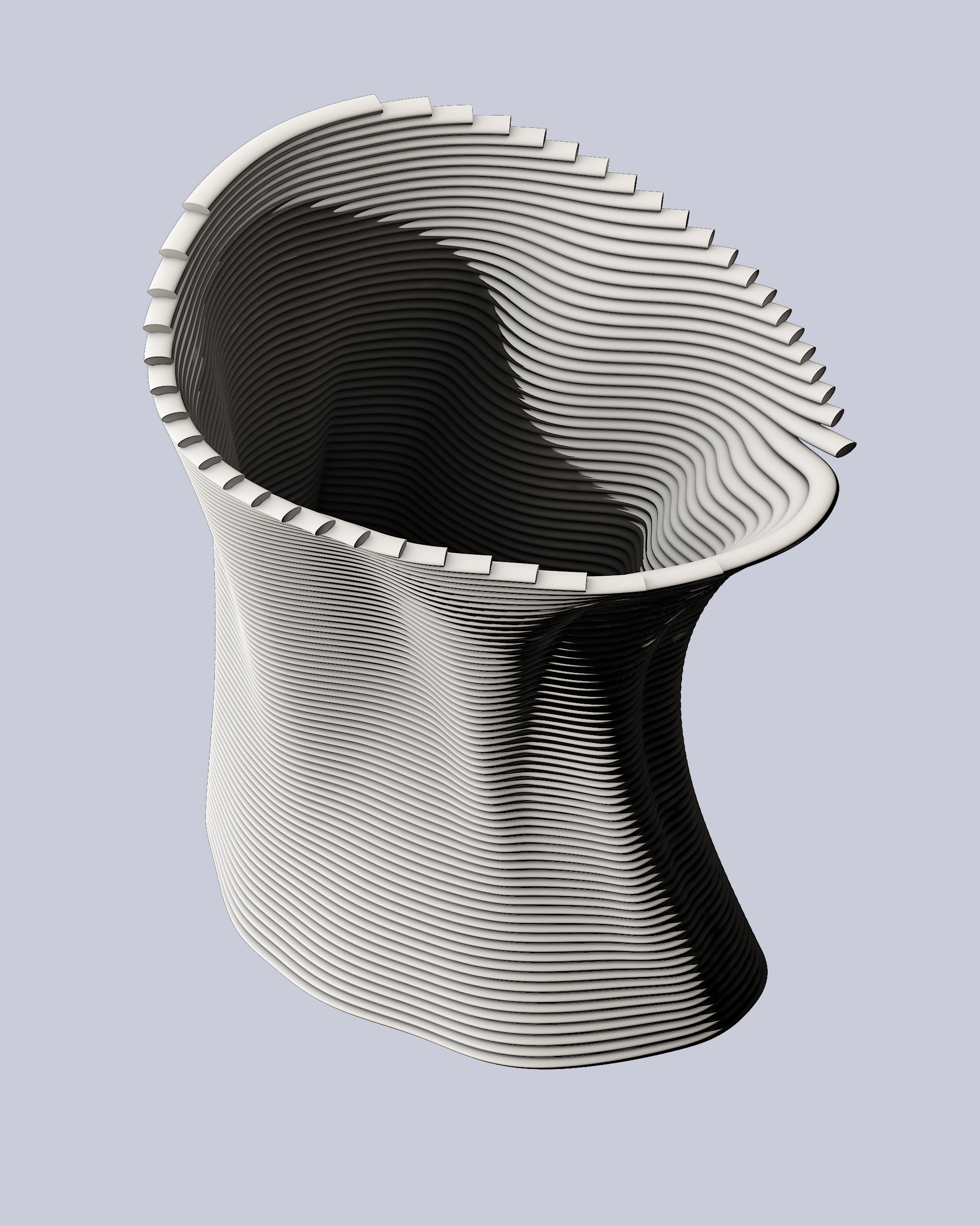

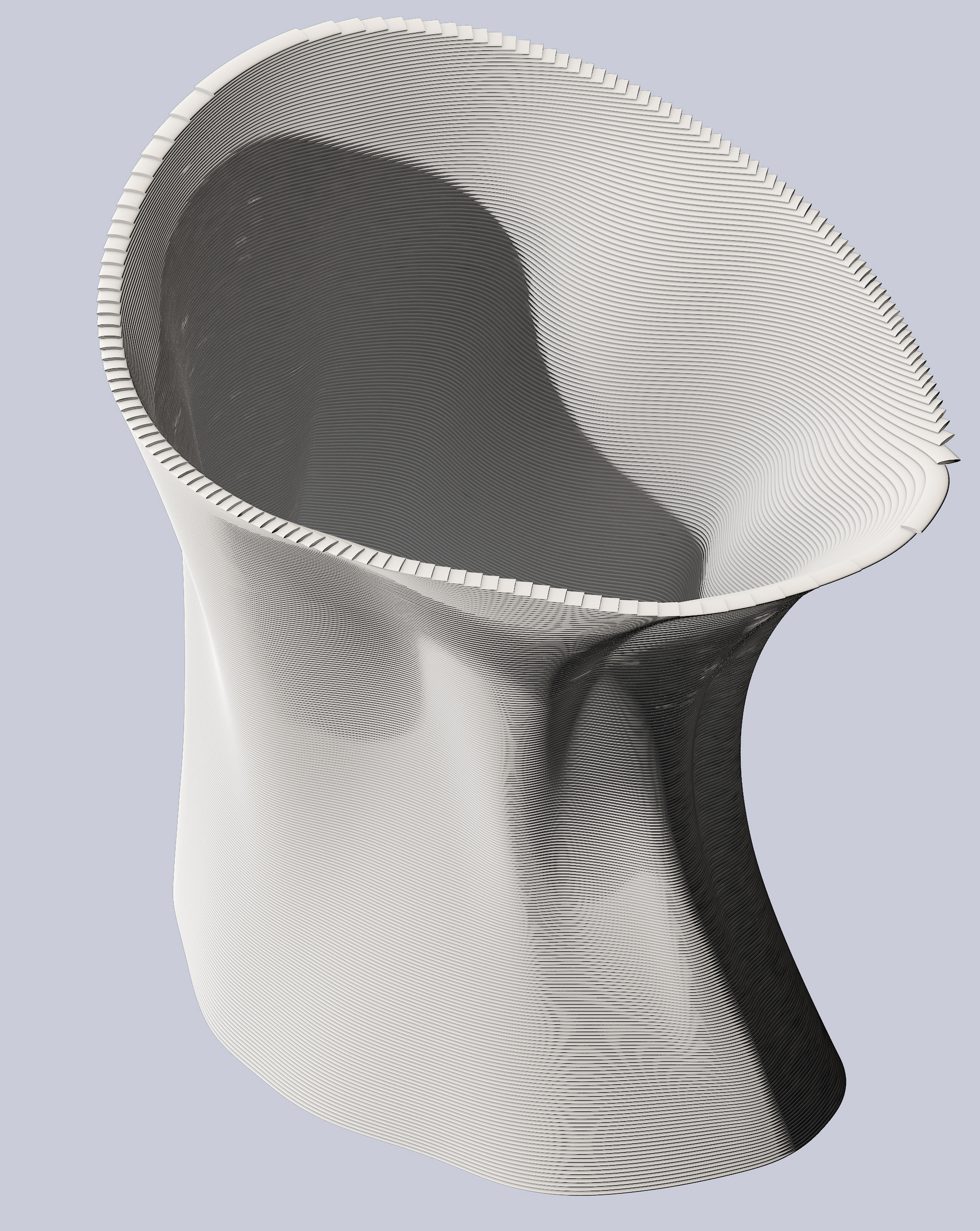

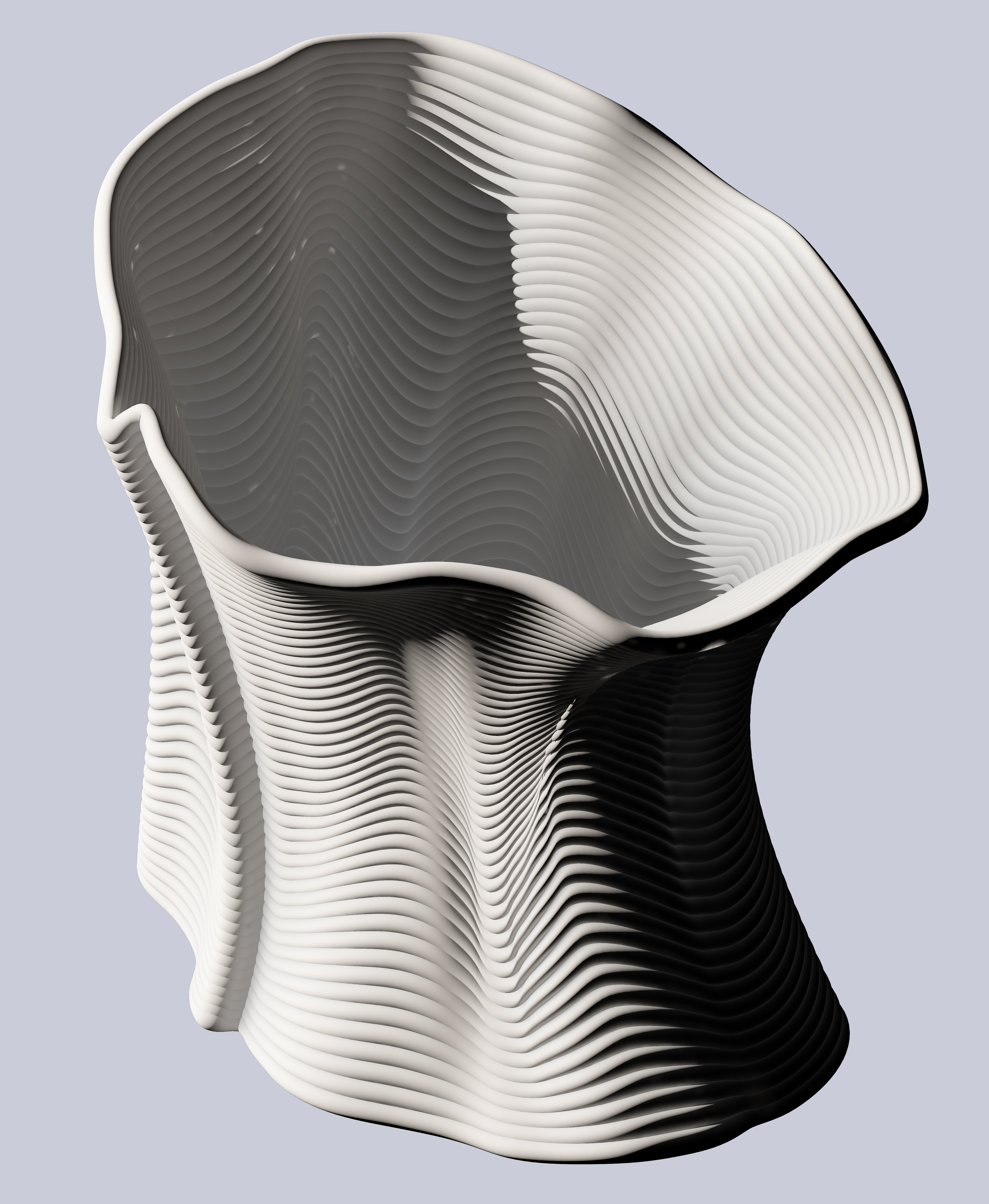

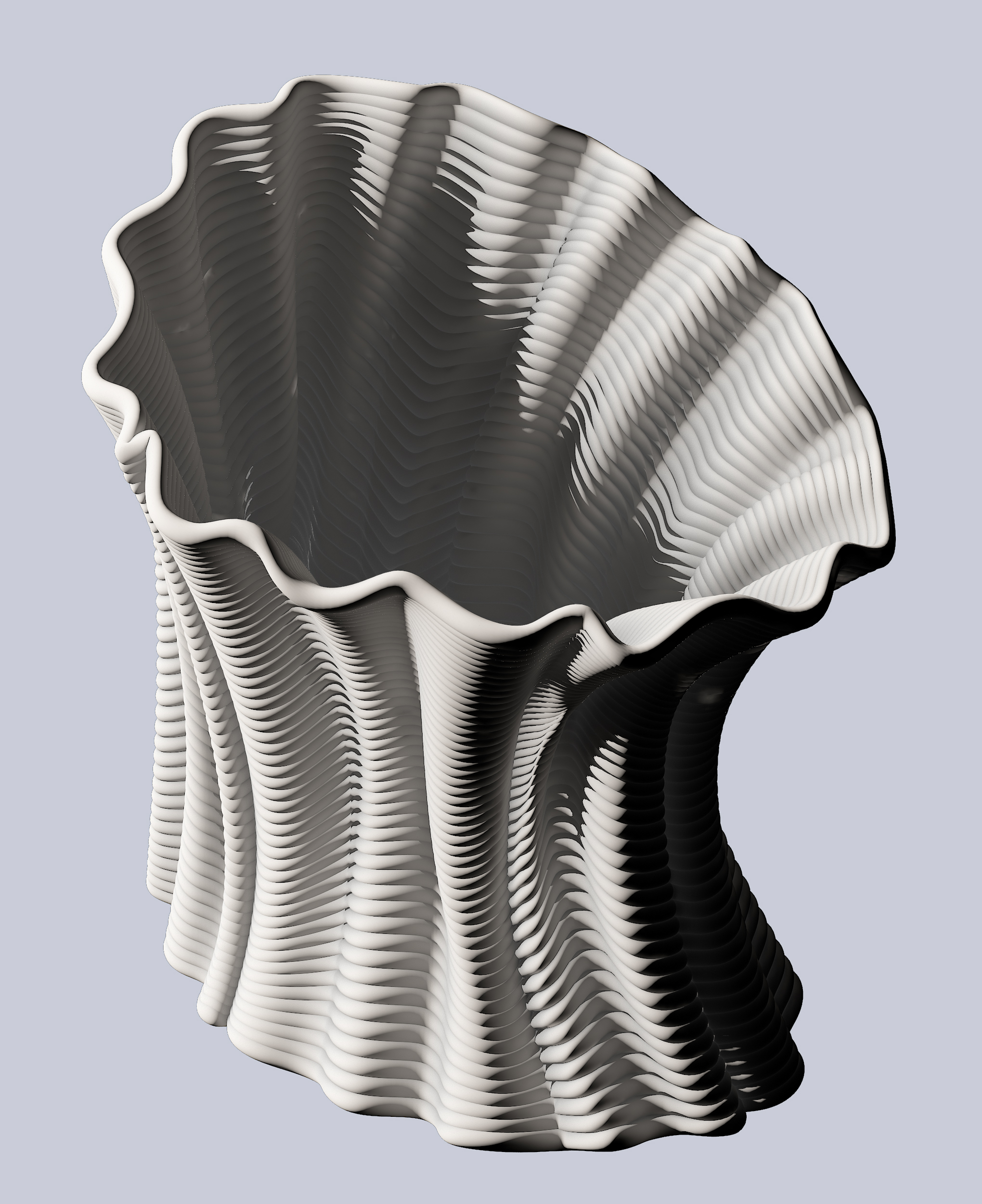

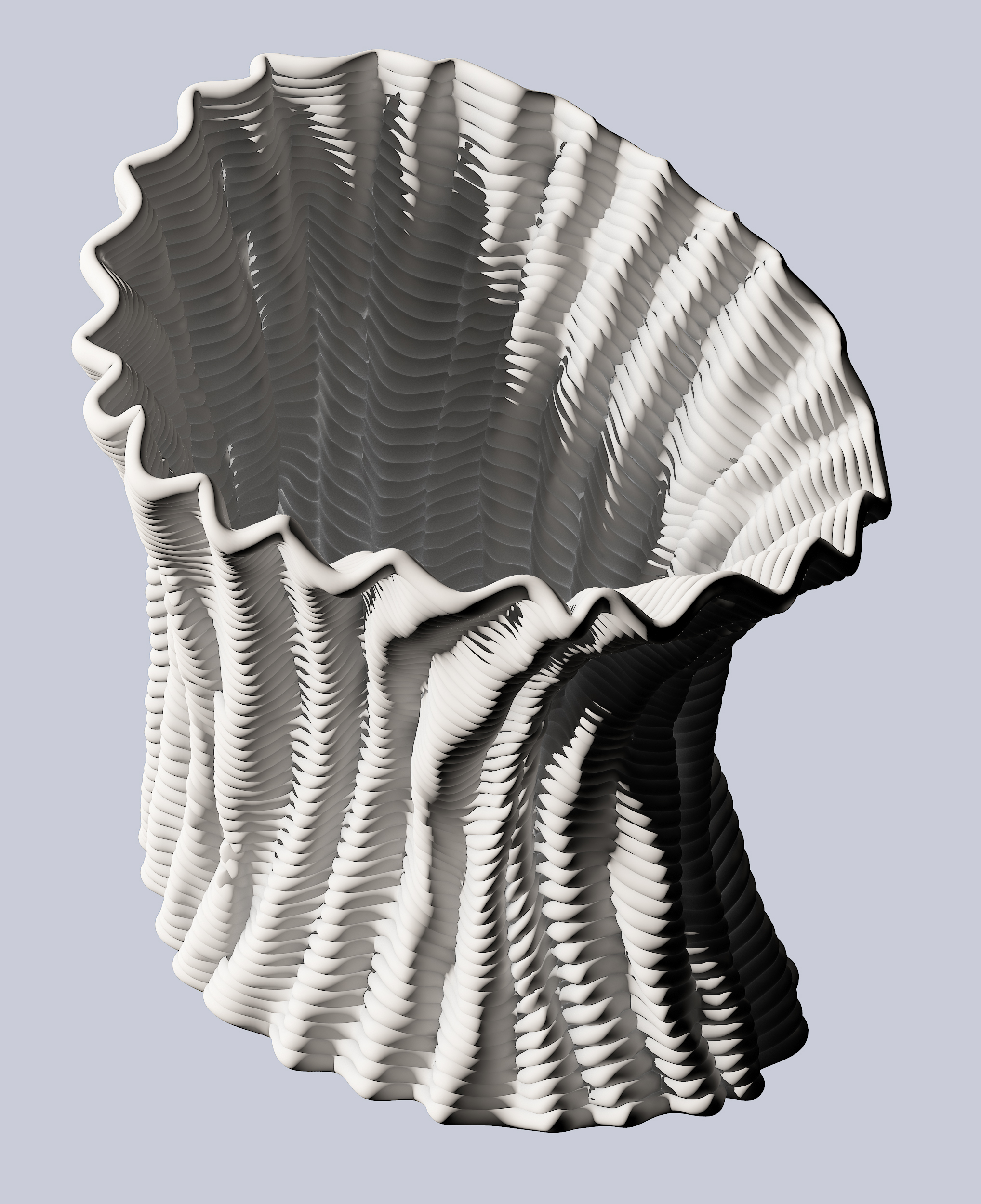

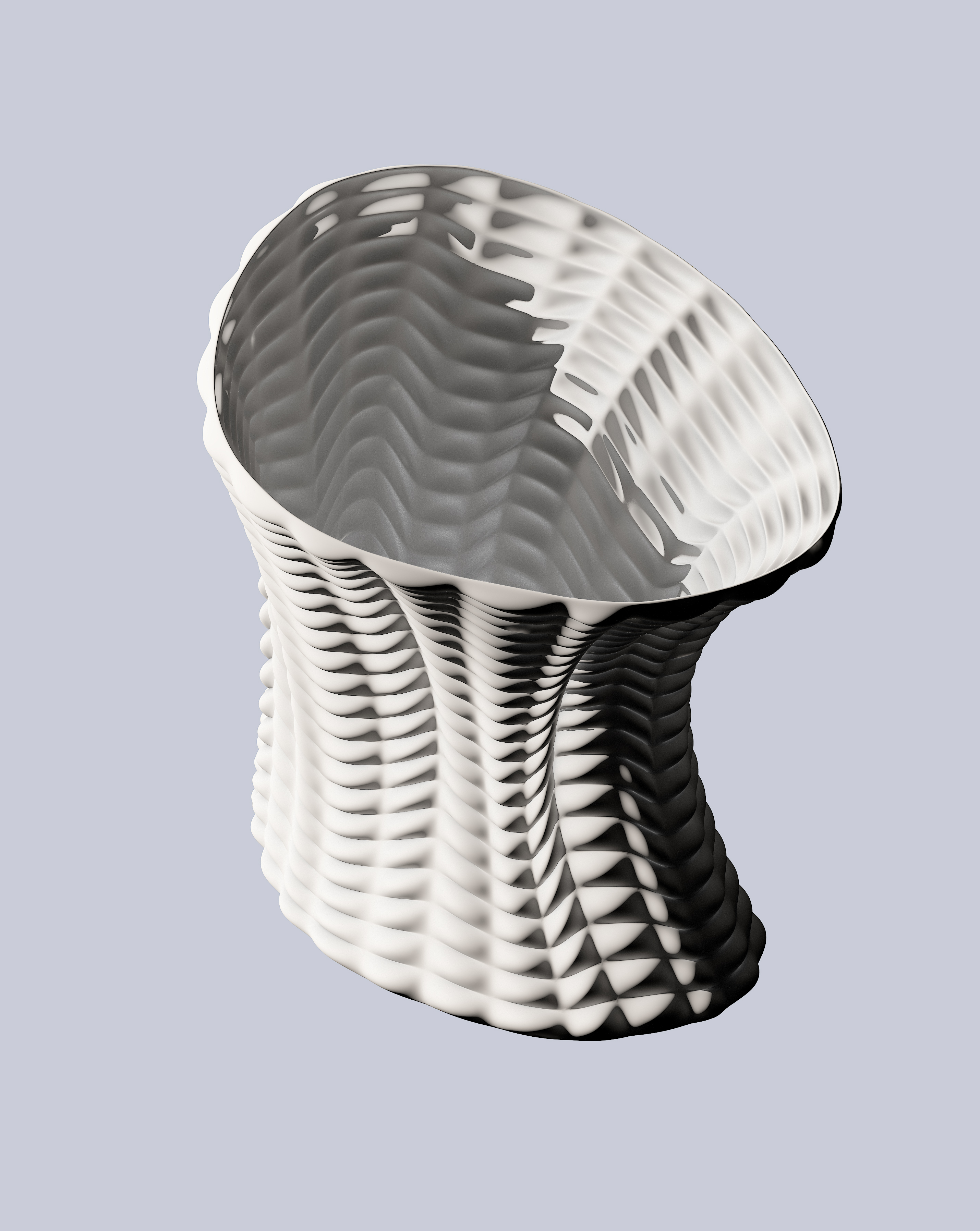

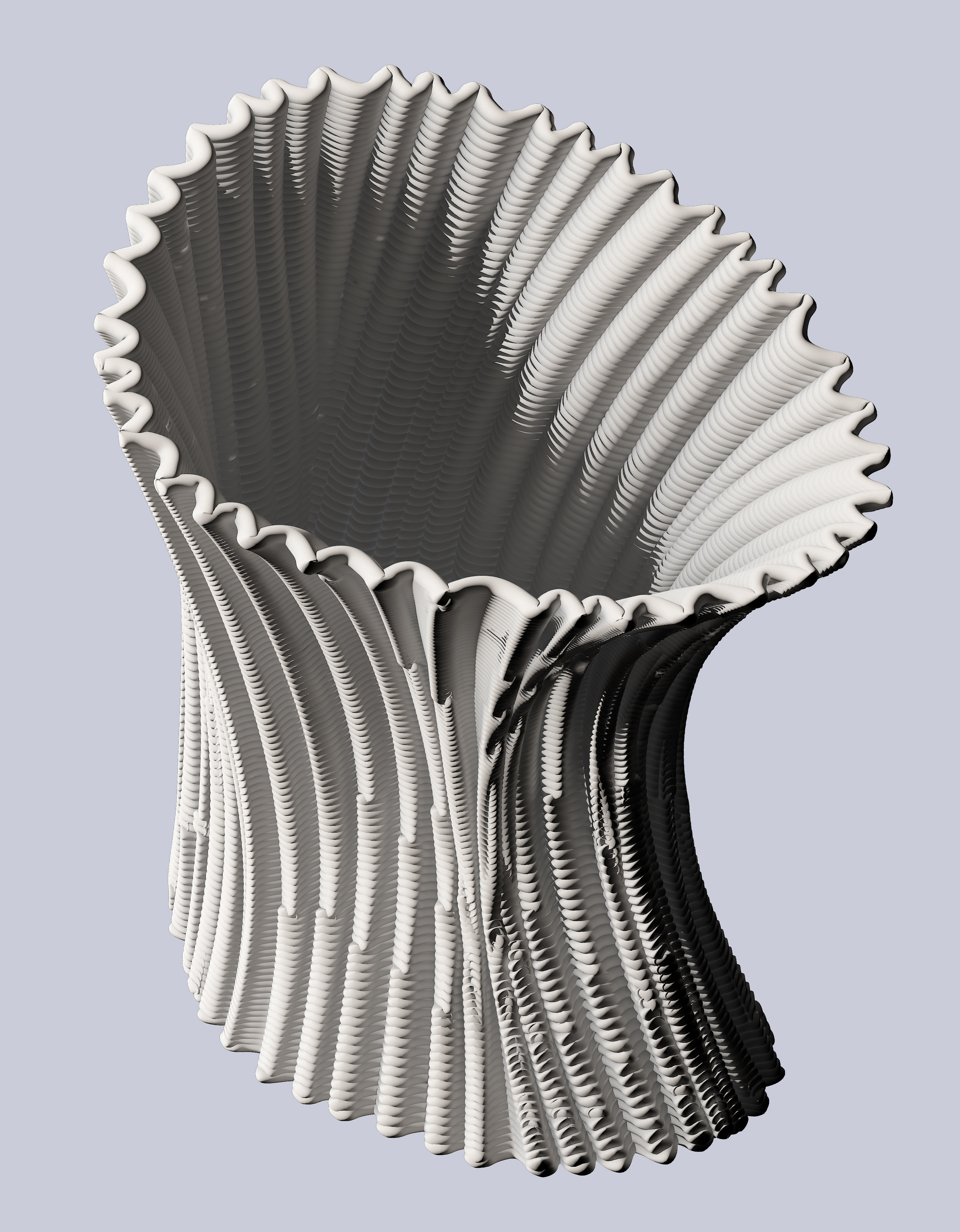

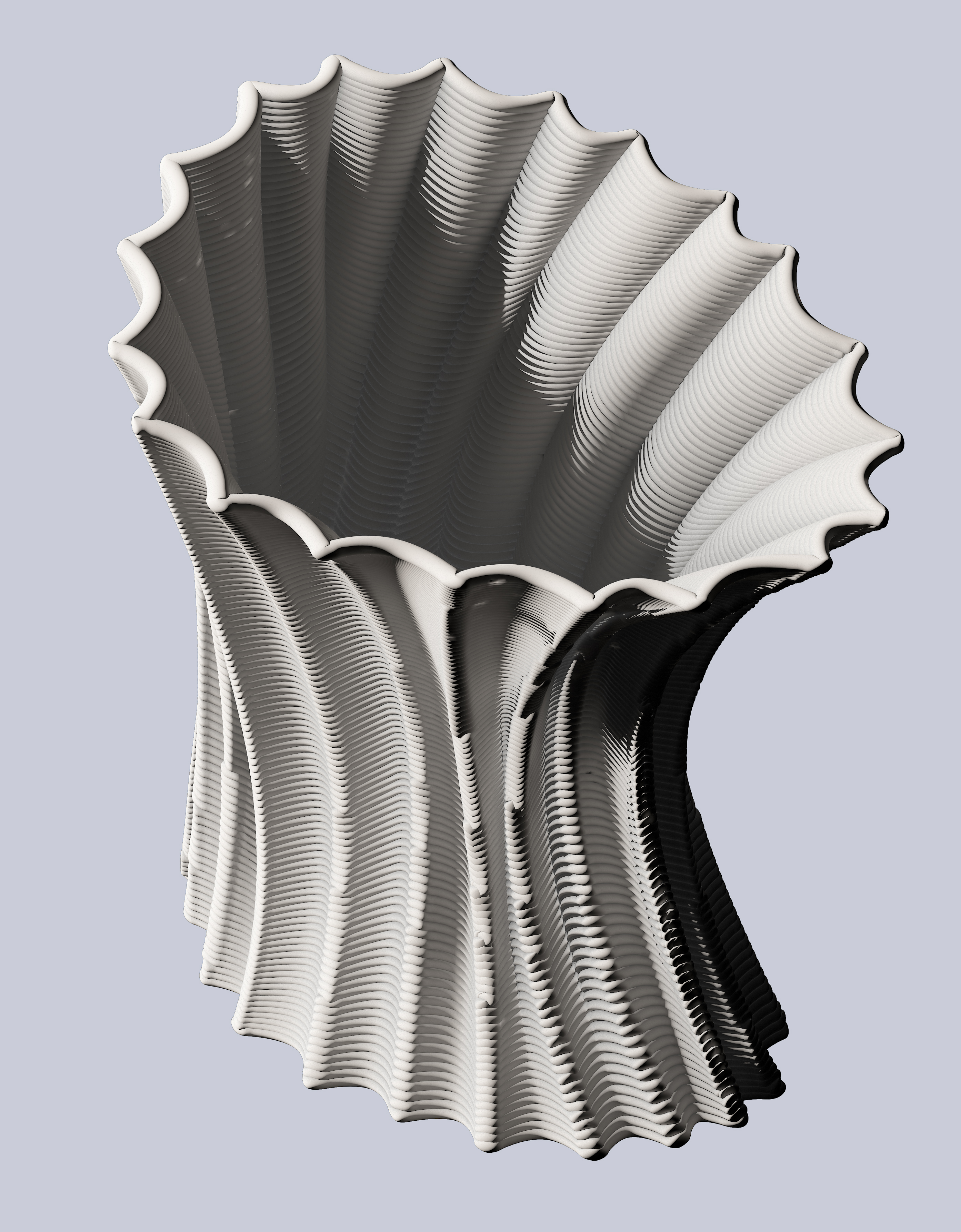

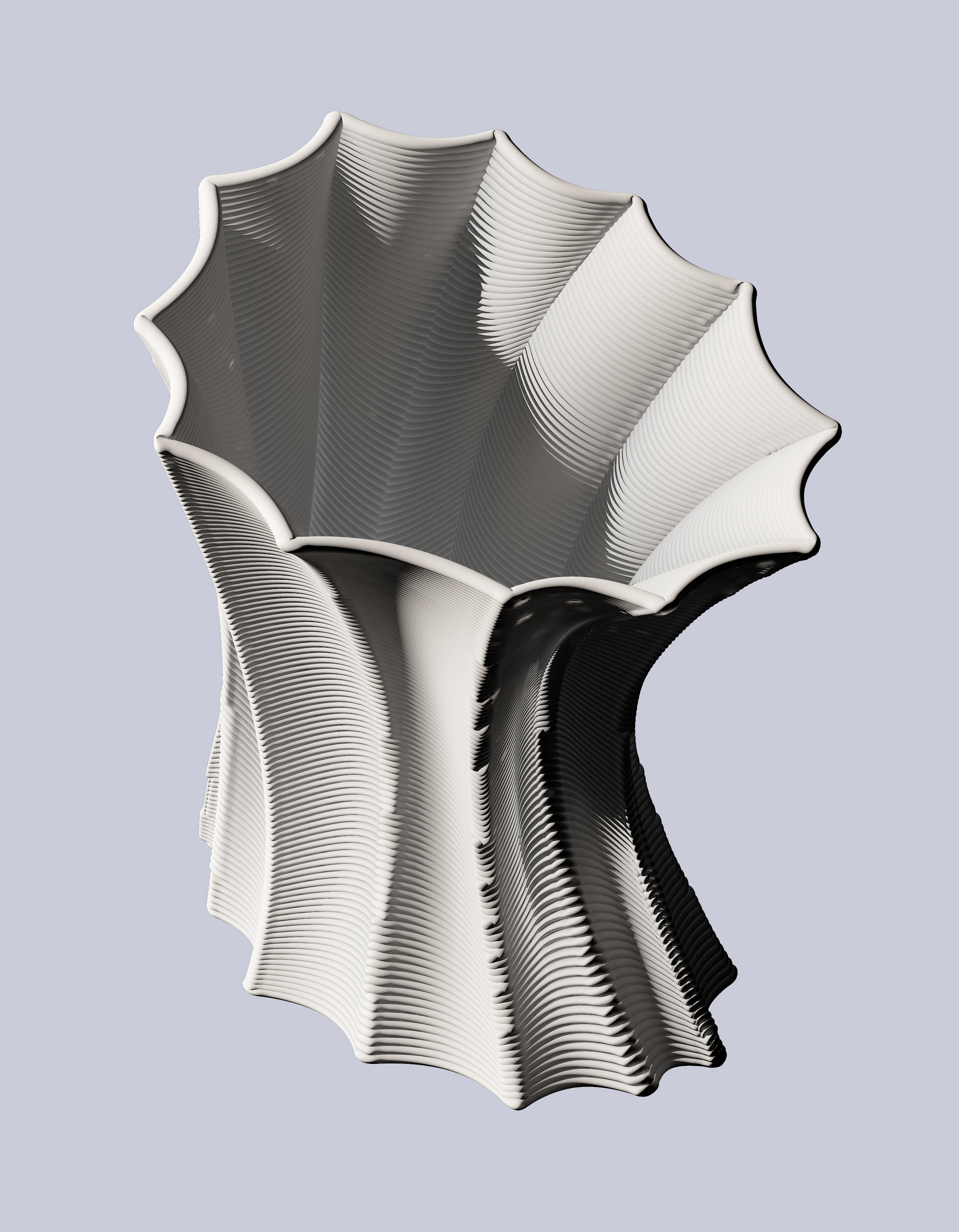

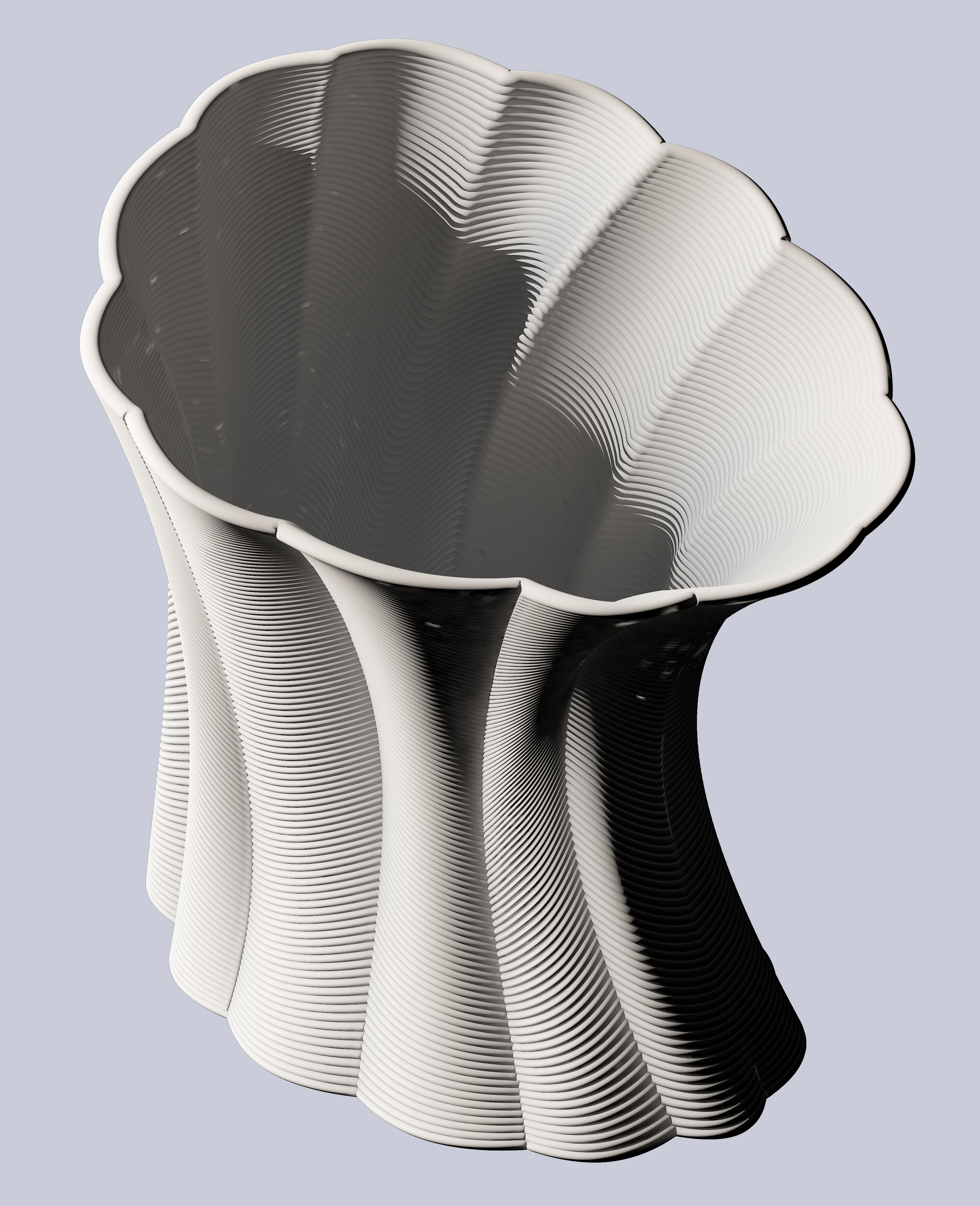

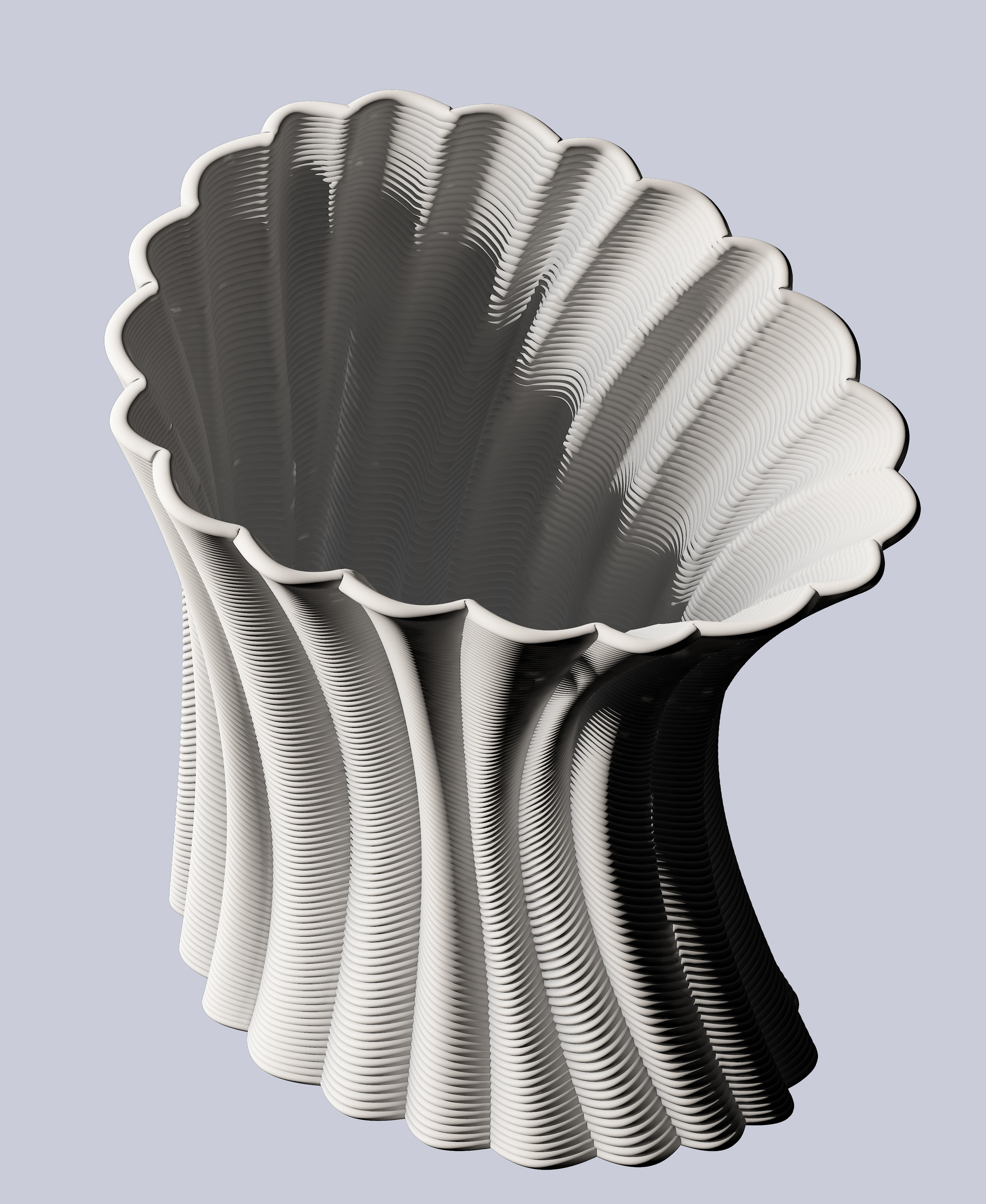

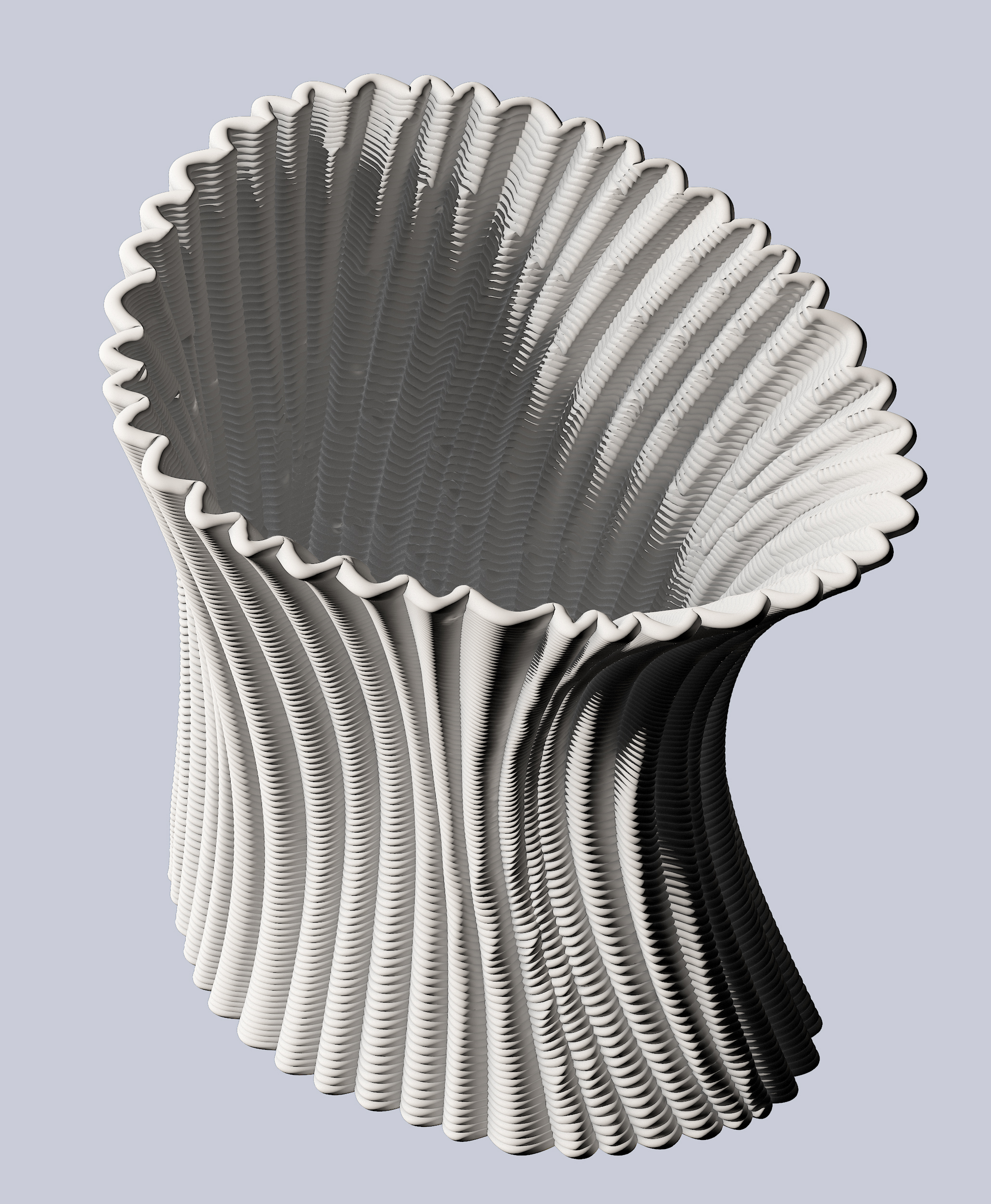

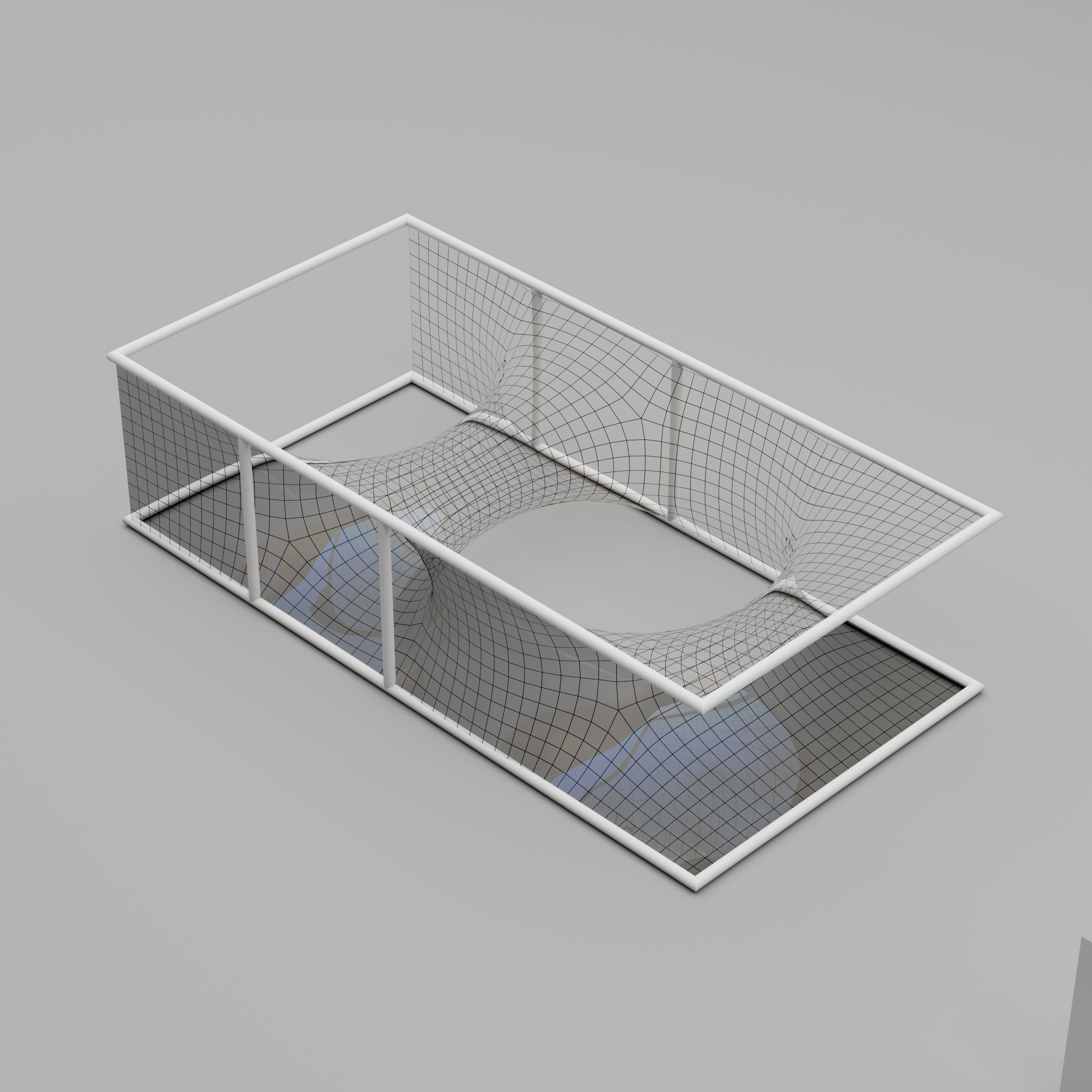

The Computing Minimal Surfaces project explores how minimal surface geometry and additive manufacturing can be combined to create innovative architectural façade systems. A minimal surface represents the smallest possible area within a given boundary — a principle observed in soap film experiments used to study natural form-finding processes.

Building on Frei Otto’s pioneering research in tensile structures, this project translates those physical experiments into digital fabrication using Fused Deposition Modeling (FDM). The use of FDM enables the design and production of lightweight, geometrically complex components with zero waste, recyclable materials, and reduced transportation costs.

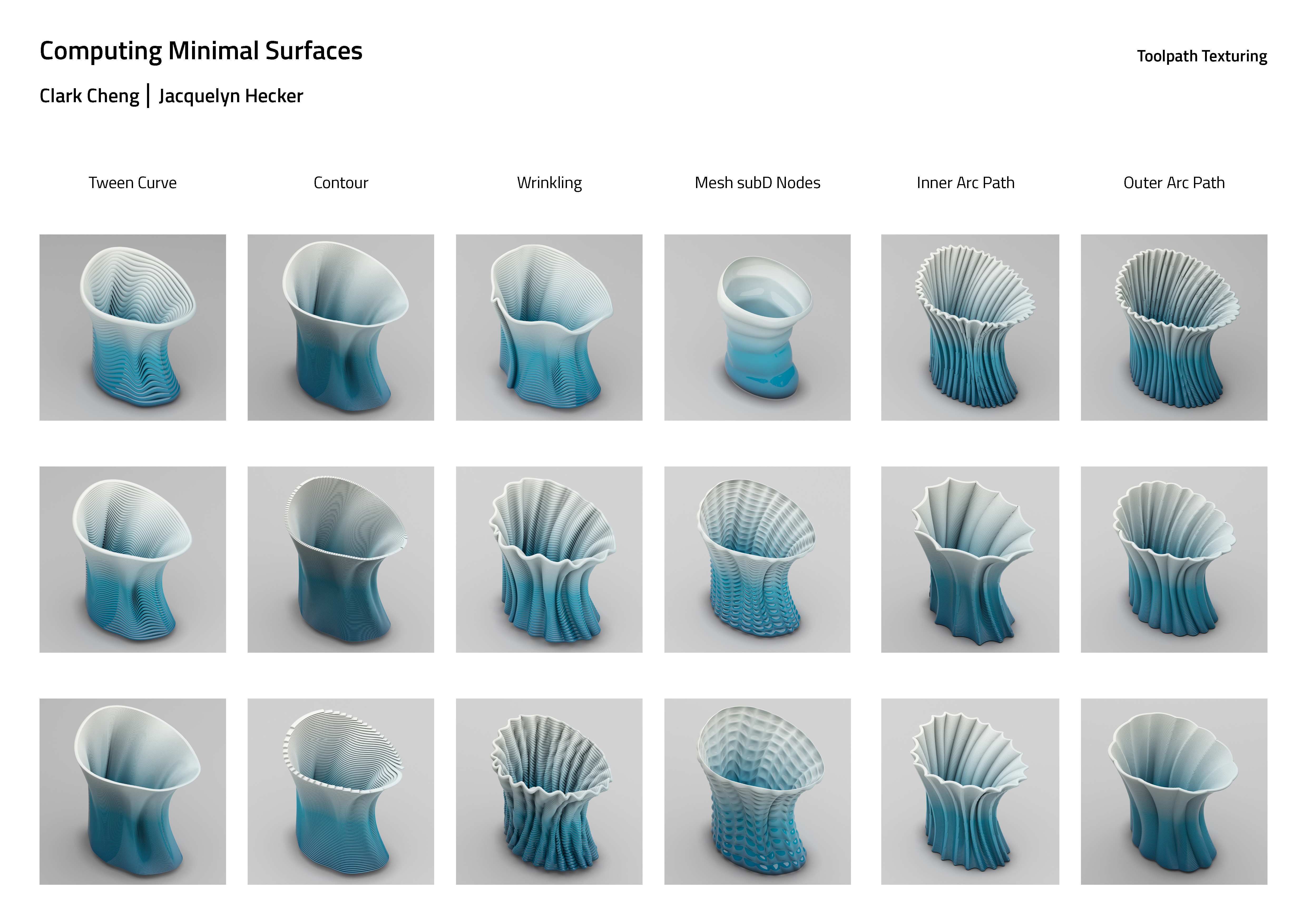

Working in pairs, students developed façade prototypes that integrate multiple functional layers, including sun shading, daylight control, natural ventilation, thermal insulation, acoustic performance, and structural optimization. Each design demonstrates how minimal surface geometries can enhance both aesthetic and environmental performance.

The process involved soap film experiments for initial form-finding, followed by 3D modeling in Rhinoceros and Grasshopper, rendering in KeyShot, and physical prototyping with PLA and concrete mixtures. This workflow represents a complete digital design-to-production pipeline.

Ultimately, the project aims to demonstrate how coupling minimal surface geometry with additive manufacturing can transform façade design and fabrication in the context of sustainable, computational architecture.

Here is the class syllabus for reference:

.png)